- All

- Choice guide

- Company

- Events

- HSM Machines

- InForm

- Investor relations

- News

- Press release

- Products

- Uncategorized

Fidia Milling Centres

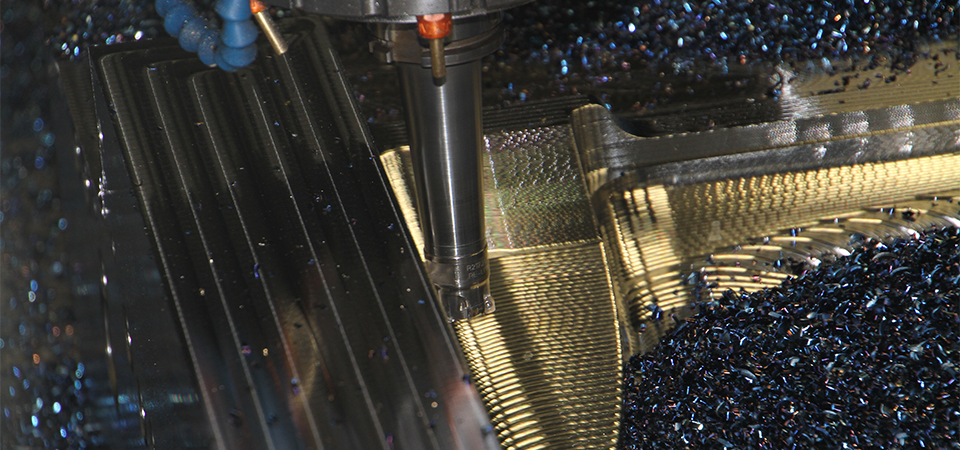

High Quality Surfaces with Fidia Milling Centres

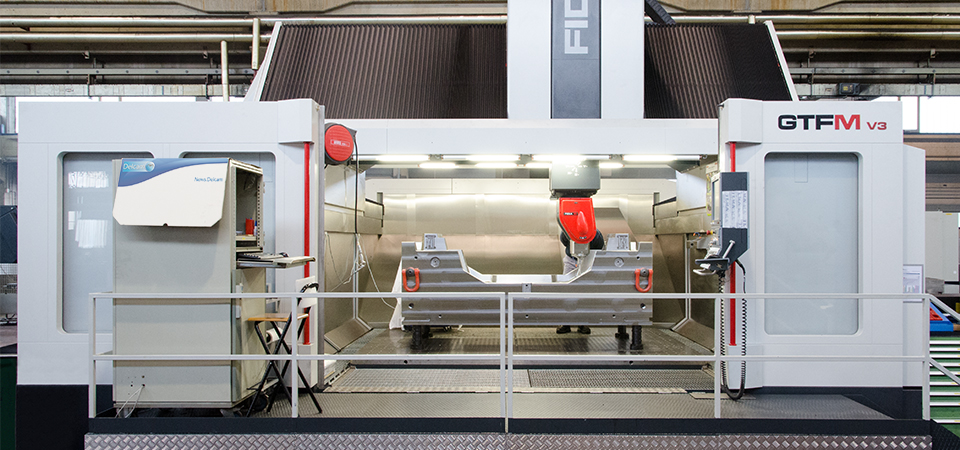

The mould makers of Farmingtons Automotive rely on a Fidia gantry machine to achieve a perfect surface for trim parts of car interiors. This new milling centre GTF3514/MA2200 comes in addition to milling machines used for roughing, considerably cutting production time and substantially improving quality of machined surfaces.

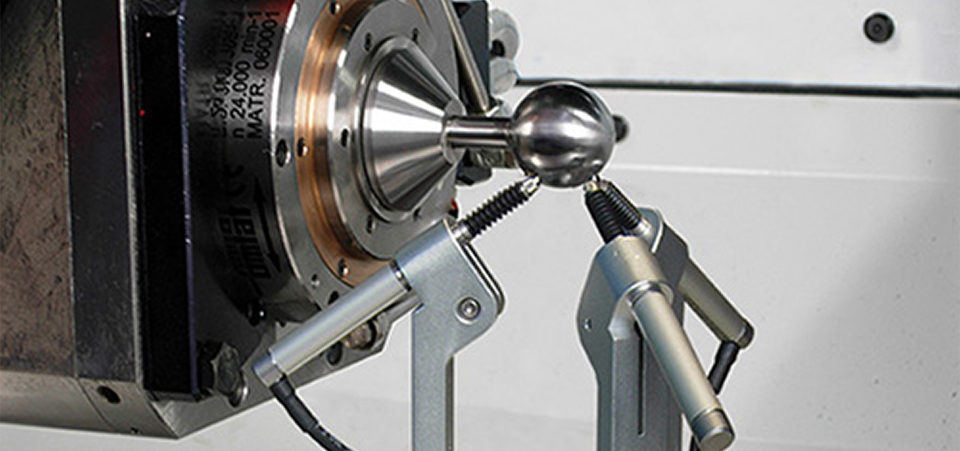

HMS®: Head Measuring System

HMS, the greatest accuracy on 5-axis machining

For the greatest accuracy on 5-axis machining

HMS is a device designed to measure and to compensate geometrical error on continuous or indexed bi-rotary heads, and on roto-tilting tables.

The system works in conjunction with the Fidia CNC.

HMS improves the accuracy and quality of 5-axis milling, without the need for complex service interventions by specialist engineers.

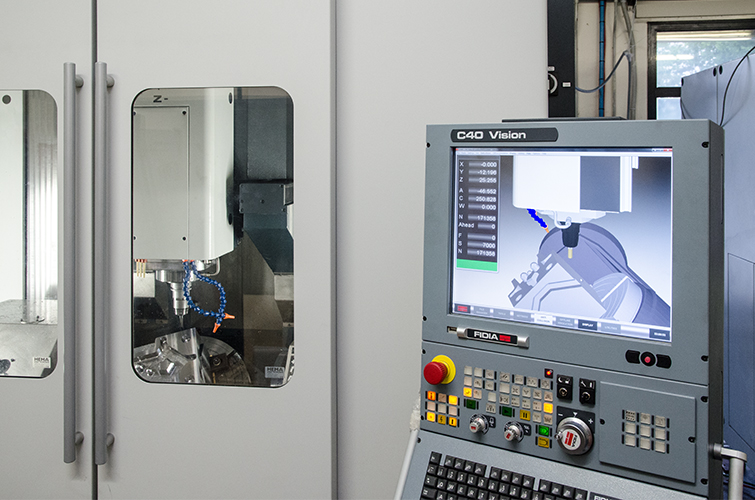

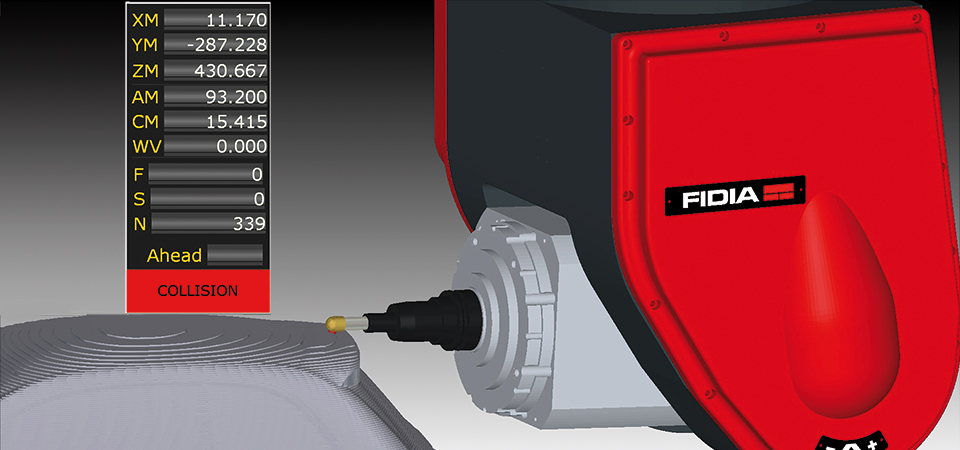

ViMill®

ViMill®, the ultimate solution to collision risks

Over 40 years ago, Fidia has been the first one introducing the “look ahead” concept: the CNC “looks ahead” the programmed tool path in order to optimize acceleration and velocity of the machine. With ViMill, this concept has been extended to safety. ViMill is a software package, where the “look ahead” function has evolved to predicting any possible collision for safer machining.

HiMonitor

iMonitor - Machine Monitoring System

Understanding makes the difference

In order to improve the production process and to get the best efficiency out of milling machines, a user needs detailed information at hand of all the operations the machine has carried out. Detailed information includes actual working hours, interruptions/breakdowns, and the machine’s most important life events. Having this information available, the user can fully identify problems that may occur and carefully plan the most appropriate interventions to improve the machine efficiency.

To achieve this target and looking at the client’s requests, Fidia decided to develop two advanced modules: the Machine Monitoring System and the Monitoring system on WEB. The former system identifies all the different machine and CNC activities registering them and then producing visual or printed reports, while the latter system allows the user to check out the machine status with a remote device such as a phone, a tablet or a PC.

Working jointly, the modules allow for close workshop monitoring, accurate cost calculations, smooth manufacturing and extremely efficient interventions.

Fidia & Ilma Plastica

Towards “zero adjustment”. Fidia GTF Gantry: quality has a new

shape.

“Today a mould is no longer a simple “open-and-shut” case, but a structured machine, a puzzle with different pieces that move via kinematics, cams and fluid dynamic criticalities; it is extremely complex and ultimately, it must be perfect to withstand the whole production cycle.” Speaking is Antonio Caraffini, third generation after Dante and grandfather, Antonio who in 1938 founded Ilma Plastica, an historic firm in Oltrona di Gavirate (VA), Italy. “Today it is essential to have excellent machinery because the market leaves no room for errors, and once they leave the factory, moulds have to be fitted to a press to start production immediately.” To hear what he thinks about the latest machine installed, a Fidia Gantry GTF3514, we have come to visit the company, one of the most important manufacturers of moulds for plastic injection moulding. As well as Company President, Antonio Caraffini, we met with Technical and Production Director, Leonardo Volponi.