DL321/M New Monolithic Compact Gantry

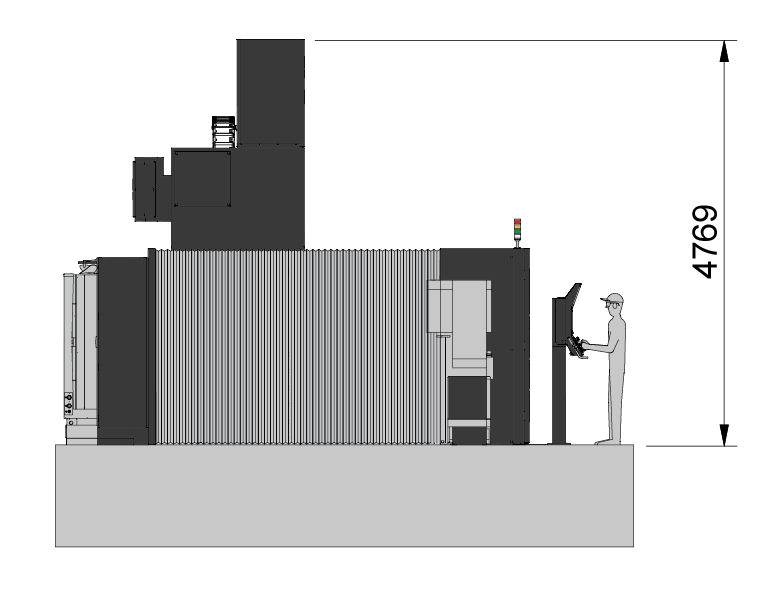

The monolithic cast-iron base includes the work-piece table. This set-up allows to install the machine on a lighter foundation slab, or directly on an industrial floor, depending on the maximum workpiece weight to be handled.

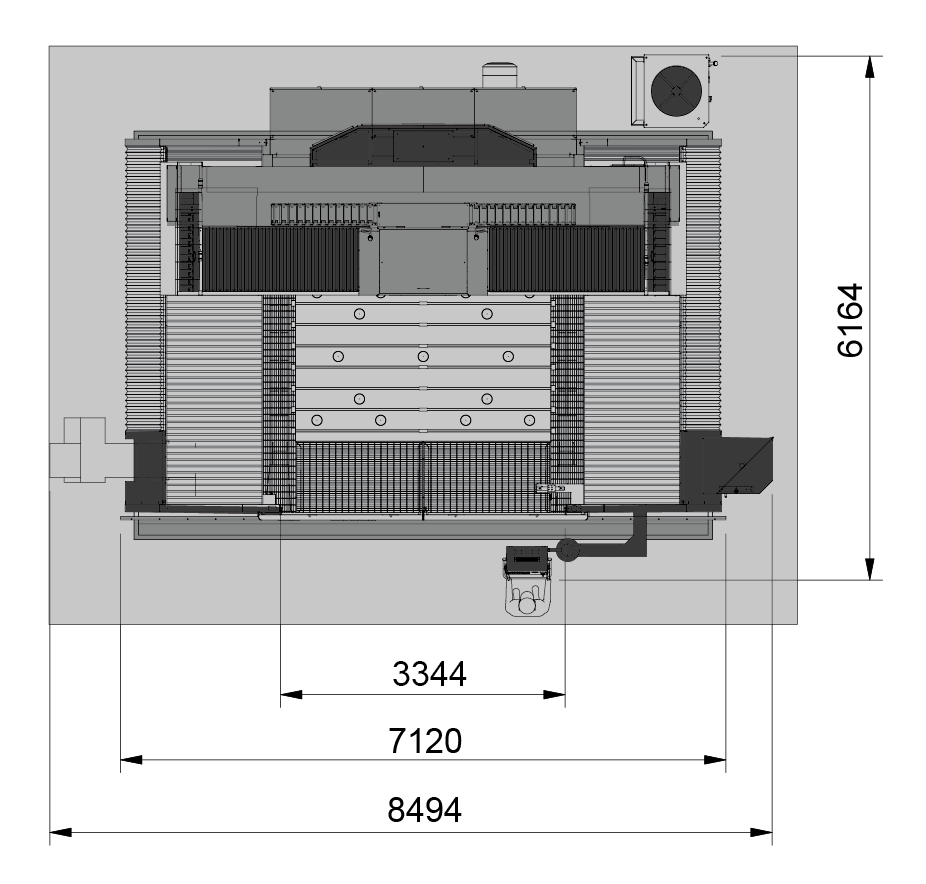

Technical specifications and Layout

| DL321/M | Features | ||

| Z axis travel | 1250mm (49”) | ||

| X Y axis feed rate | 60m/min (2362ipm) | ||

| Z axis feed rate | 30m/min (1180ipm) | ||

| Workpiece clamping area dimension | 3000x2000mm (118” x 79”) | ||

| Milling spindles | M5A/55-24, M5A/65-15 |

||

Working area

On DL321/Q milling machines the working table is made of cast iron as an independent part, fastened to the floor, while on DL321/M the table is integrated into the monolithic structure of the machine. The surface of the workpiece table has T slots to clamp the parts. The DL321 machines combine a compact footprint with a remarkable working area.

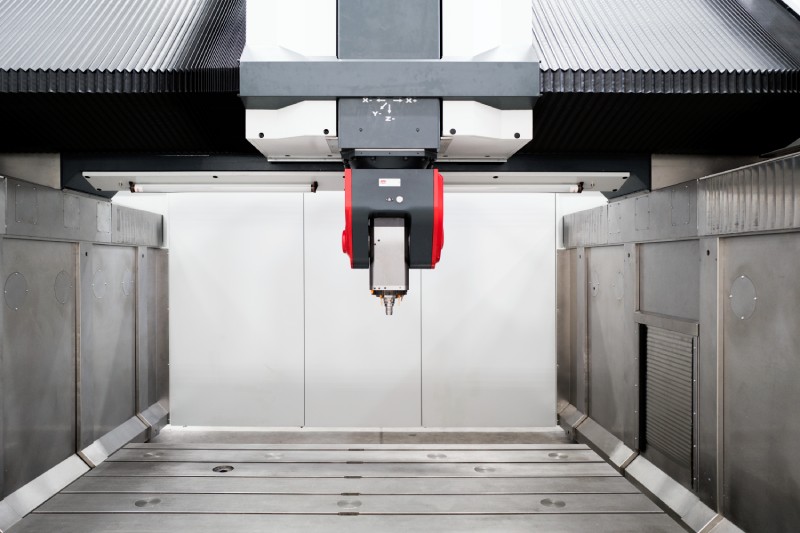

Bi-Rotary M5A head

M5A head enhances the high-speed cutting performances of D321 line and fits over a wide range of applications. It is built around a cast iron structure meant to deliver stiffness and thermal stability during demanding machining on steel, cast iron and aluminum.The compactness and the geometry structure of the head enable to reach the most difficult areas and therefore to use shorter tools.

The axes cinematic chain is provided with life-time automatic backlash recovery system and it is able to perform 0.001° resolution. The high dynamic of the axis of M5A head allows the application of the D321 line in 5 axis high speed machining. The same head can be used in 3+2 axes positioning mode, stiffly clamping the rotary axis by means of powerful hydraulic breaks, exploiting the maximum torque and power of the spindle.