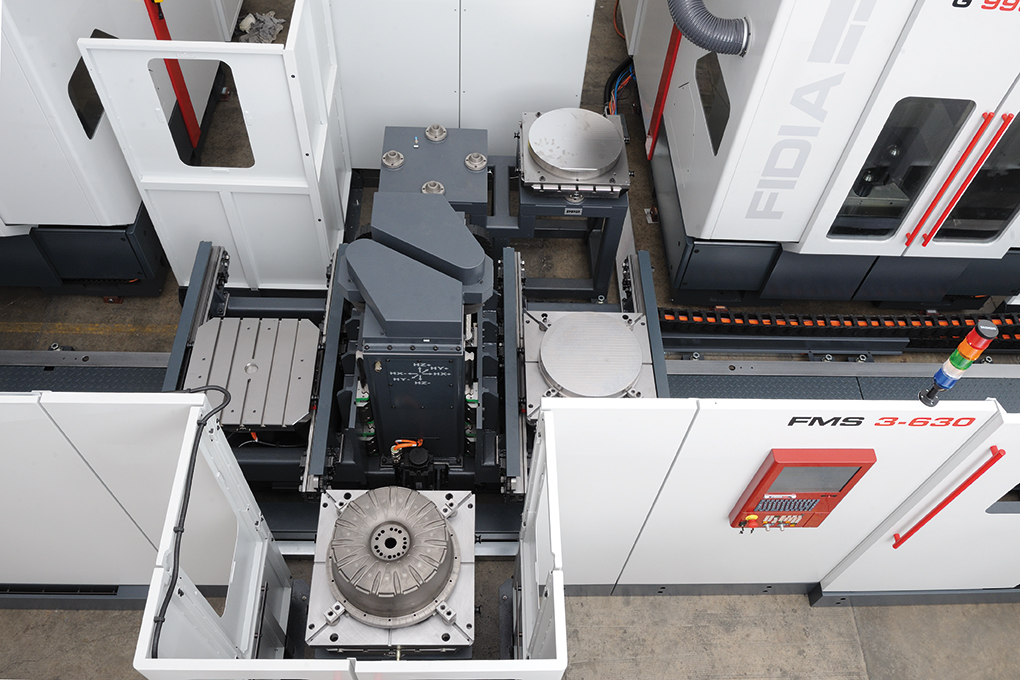

FMS

Flexible Manufacturing System

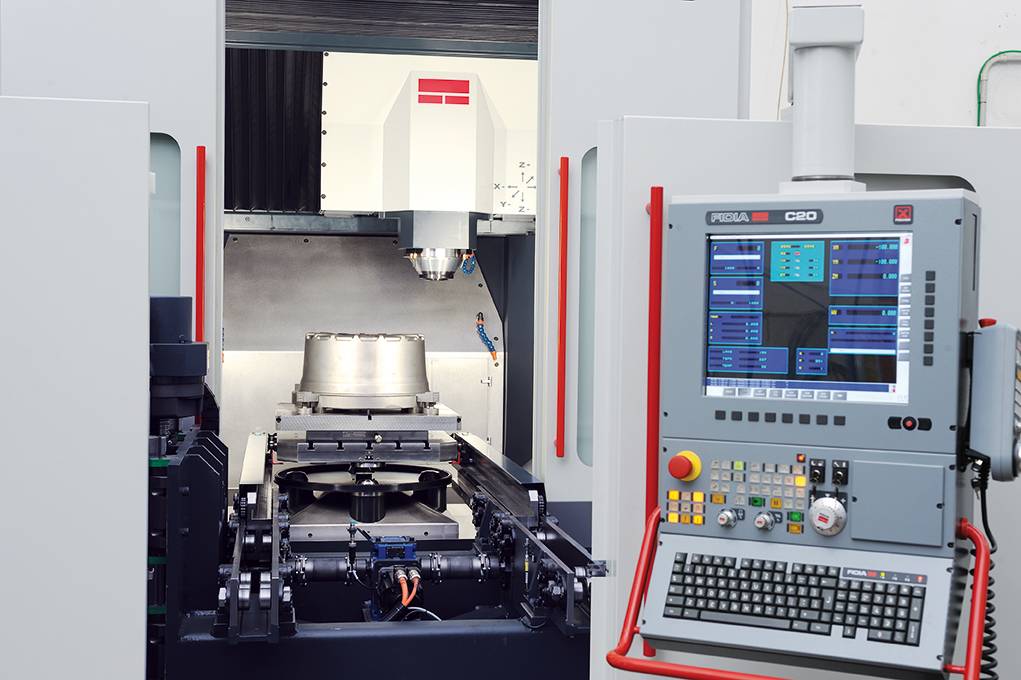

The new FMS system designed by Fidia is equipped with a sophisticated software that optimizes and exalts its operative characteristics. This system is the Fidia answer to the more and more pressing request of increasing the workshop automation level, and integrates a powerful and versatile pallet system.

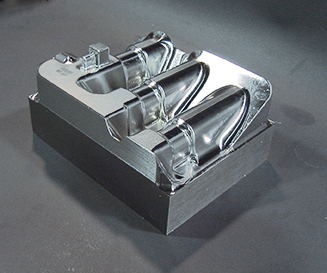

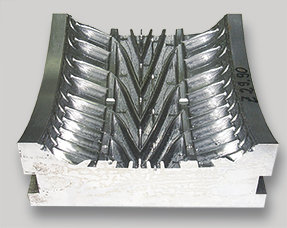

The FMS platform serves independent working islands of minimum 2 machines each, and allows for the complete machining of complex components in 3 or 5 axes, starting from the rough part.

This system is the ideal solution for a highly developed workshop environment, requiring the best standards of automation levels.

The powerful dedicated software automatically manages and optimizes the production flow without intervention of the machine operator. Such a way of functioning pursues the following goals:

- reduction of waiting times;

- simplification of programming;

- optimization of tool wear-out;

- full monitoring of production flow;

- reduction of human error risks;

- never-ending 7/7 & 24/24 production.

Each machine can be also used in a standalone way, nonetheless granting the normal functioning of the FMS system with the other machines.

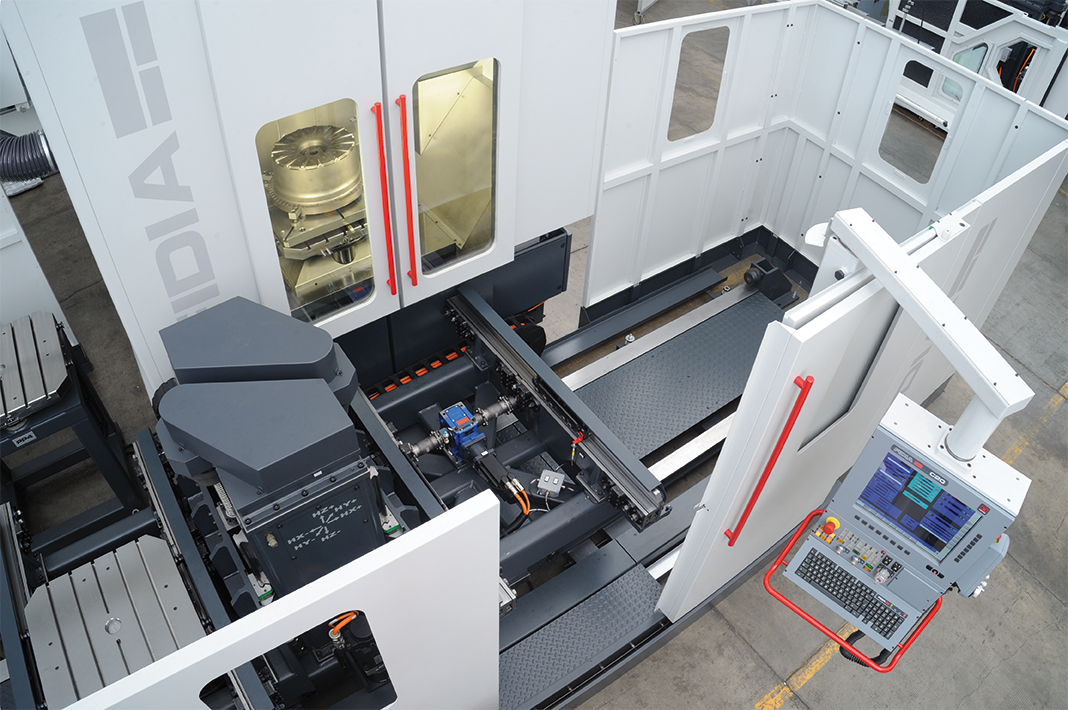

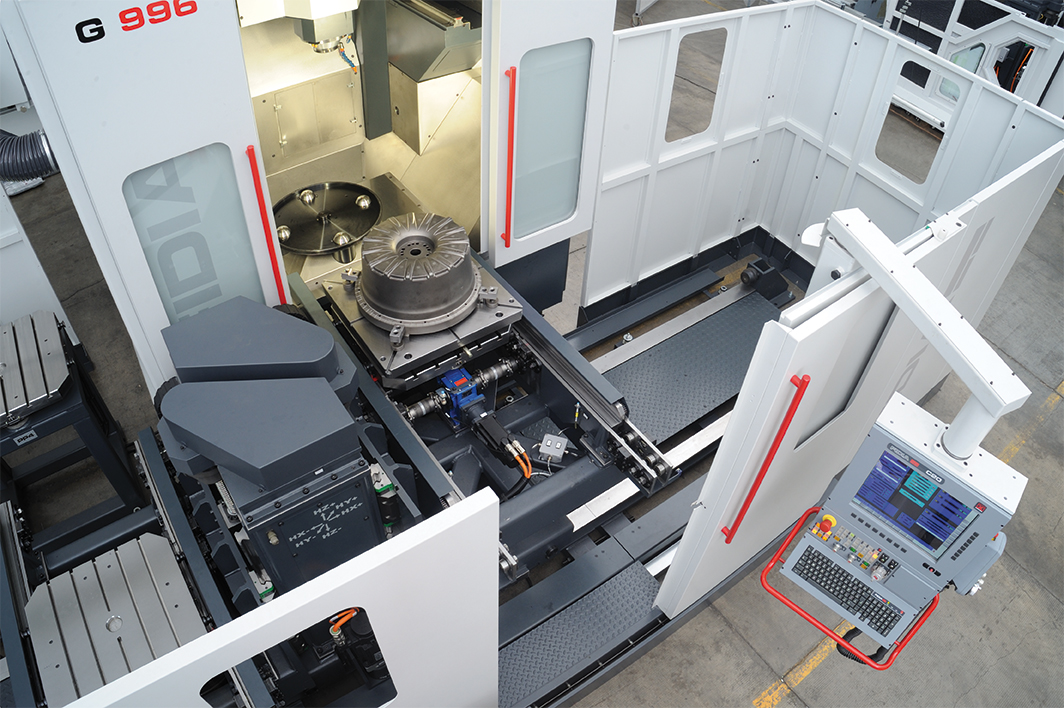

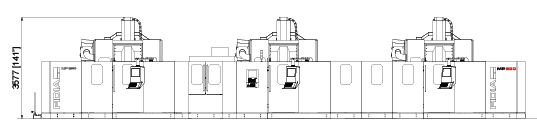

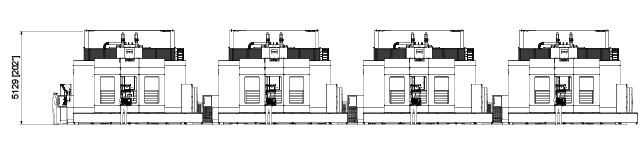

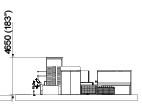

FMS - G996

Island configuration

- No. 1 G996 machine for roughing out;

- No. 2 G996 machines for finishing;

- No. 1 automatic pallet change system;

- No. 1 manual loading/unloading station;

- No. 4 stacking stations;

- No. 6 pallets;

- Pallet capacity 2000 kg (4409 lbs);

- Total length of installed system 17 m (670“).

The system can also work in unmanned machining mode.

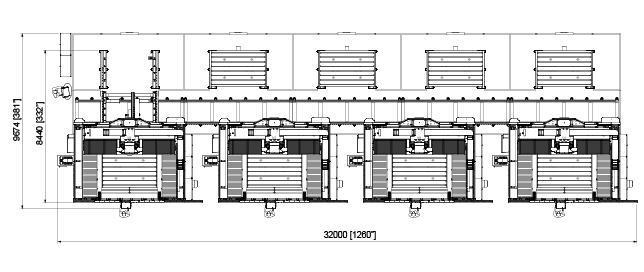

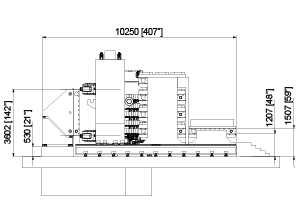

FMS - D321/M

Island configuration

- No. 4 D321/M machines;

- No. 1 automatic pallet change system;

- No. 5 stacking stations;

- No. 8 pallets;

- Pallet capacity 15000 kg (33069 lbs);

- Total length of installed system 32 m (1260“).

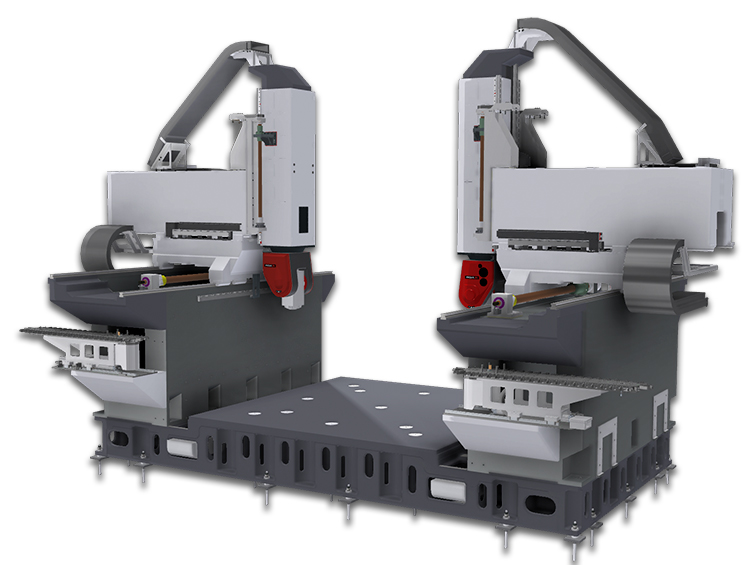

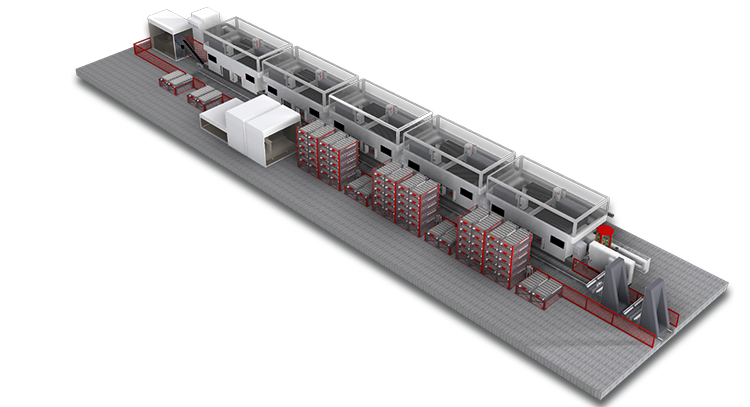

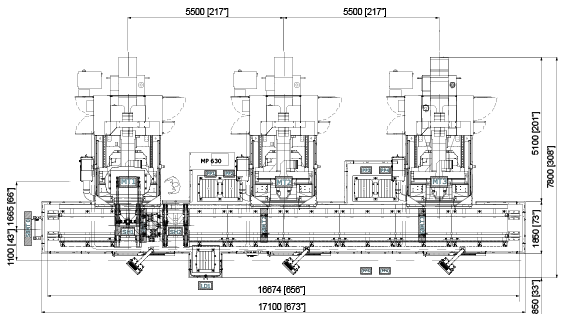

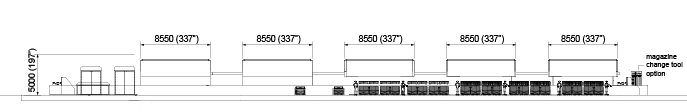

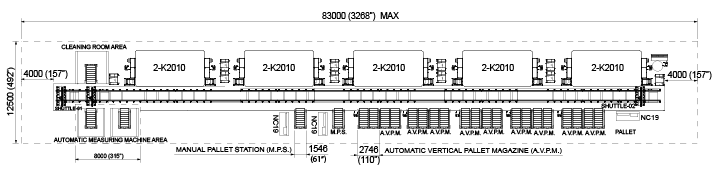

FMS - K-2010

Island configuration

- No. 5 2-K2010/M Boxer machines;

- No. 1 automatic pallet change system;

- No. 5 pallet storage stations for manual loading/unloading;

- No. 5 vertical stacking stations with storage capacity for 6+6 pallets;

- No. 60 pallets measuring 2000x1000 mm (78“x 39“);

- Pallet capacity 3000 kg (6613 lbs);

- No. 1 centralized chip conveyor system;

- No. 1 centralized tool magazine;

- Total length of installed system 83 m (3268”).

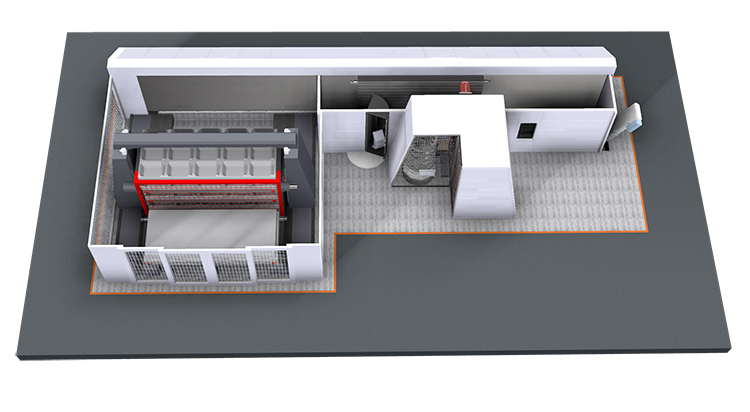

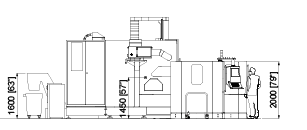

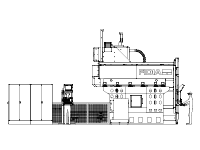

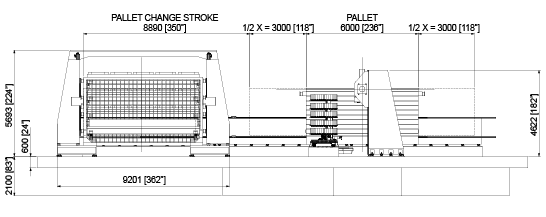

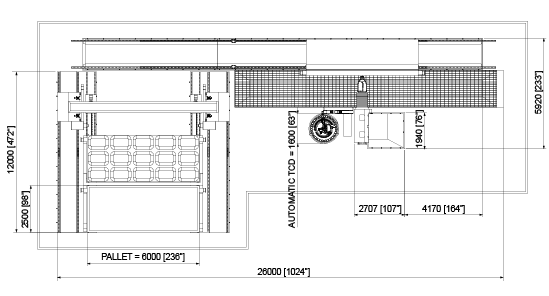

FMS - HTF/T

Island configuration

- No. 1 HTF/T machine;

- No. 1 automatic pallet change system;

- No. 1 loading/unloading station;

- No. 4 stacking stations;

- No. 6 pallets;

- Pallet capacity 6000 kg (132278 lbs);

- Total length of installed system 26 m (1023”).