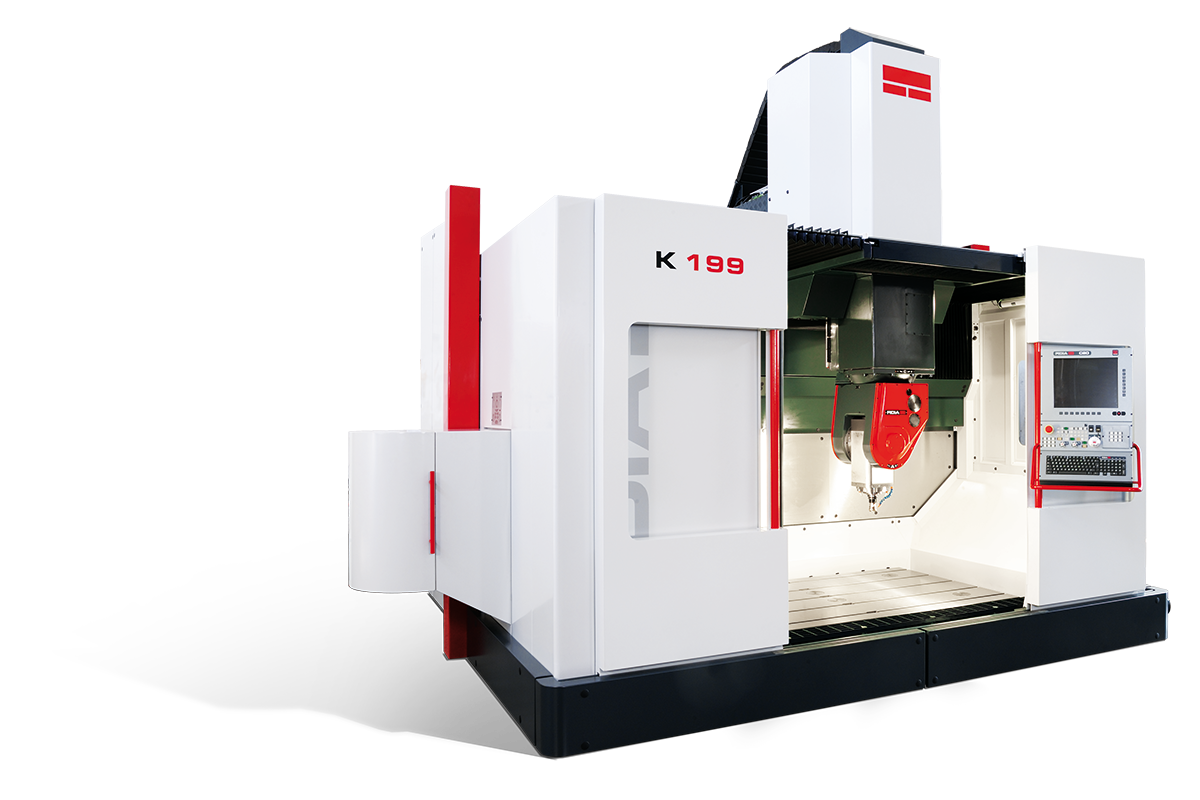

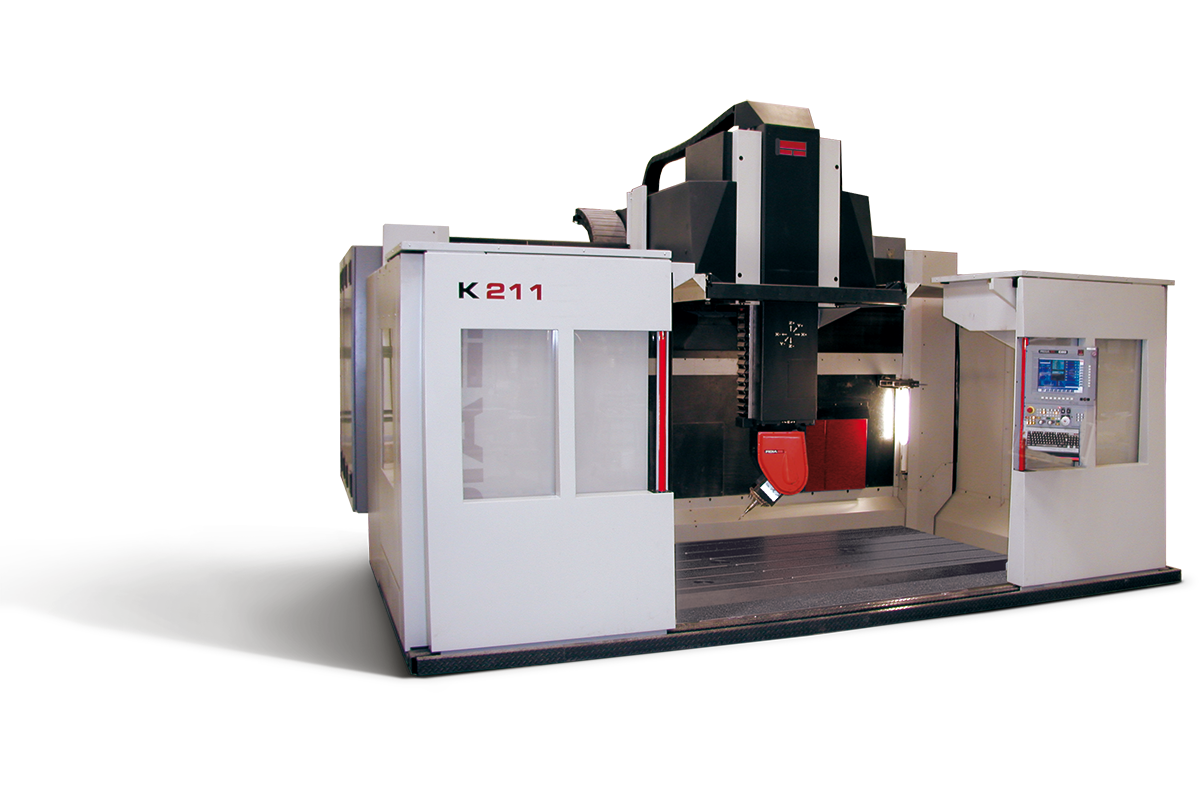

K SERIES

Technical solutions

Fixed bed structure

The choice of a fixed bed type structure was determined by the criteria below:

- constancy of the forces independently of the weight of the workpiece, allowing for optimum milling quality;

- optimum visibility of the part being machined;

- wide range of possibilities for customization.

The “high bed” version allows for a reduction in the moving masses giving superior dynamic performance.

The bed is made in cast iron, while the mobile parts of the equipment of the 3 axes are made of steel in order to obtain the best mass-rigidity ratio. The fixed cast iron worktable is suitable to grant high loading capacities.

The components

The generous dimensions of the guides and the high number of rolling shoes give the system a balanced rigidity. The digital technology used for the axis drives optimizes the machine dynamic behaviour, resolution and machining accuracy. Maximum accuracy and its maintenance over time are guaranteed by the direct type transducers for both linear and rotary axes.

Thermal stabilization

The significant reduction in thermal drift, ensuring greater accuracy during long finishing and re-machining operations, is achieved thanks to a controlled temperature circuit acting on the machine’s most sensitive parts.

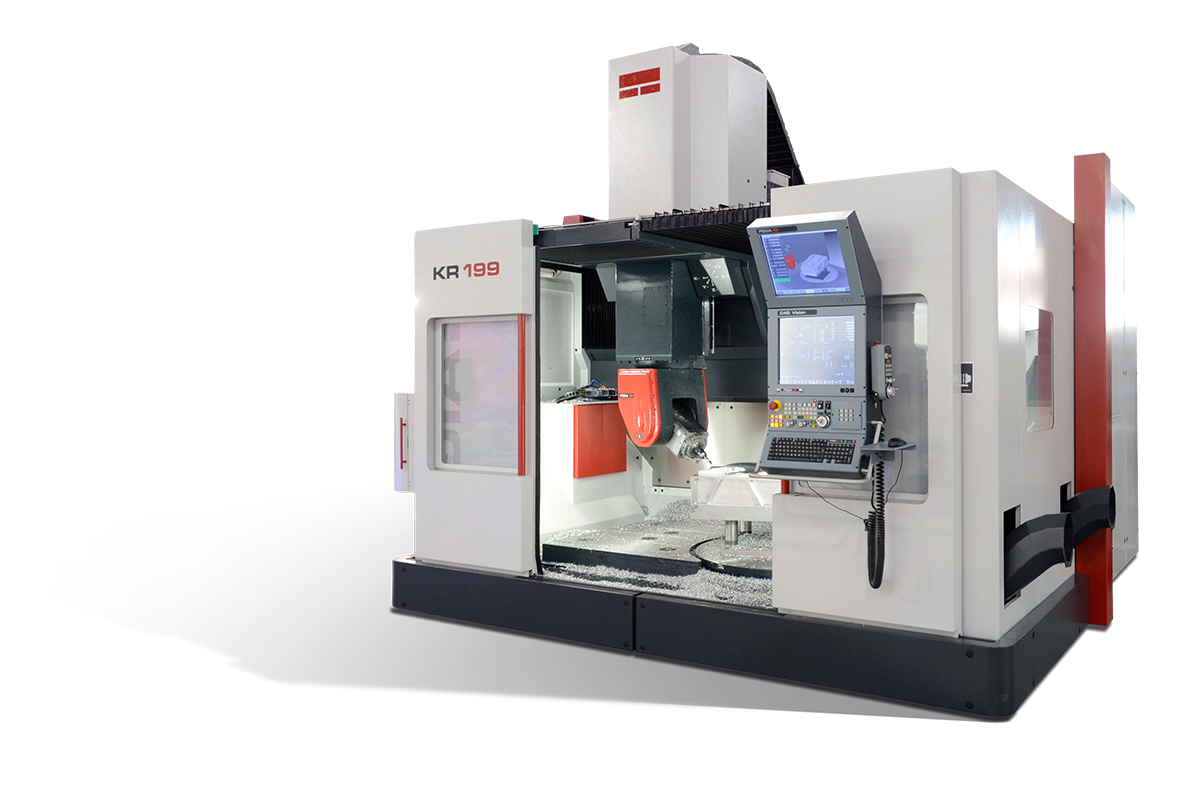

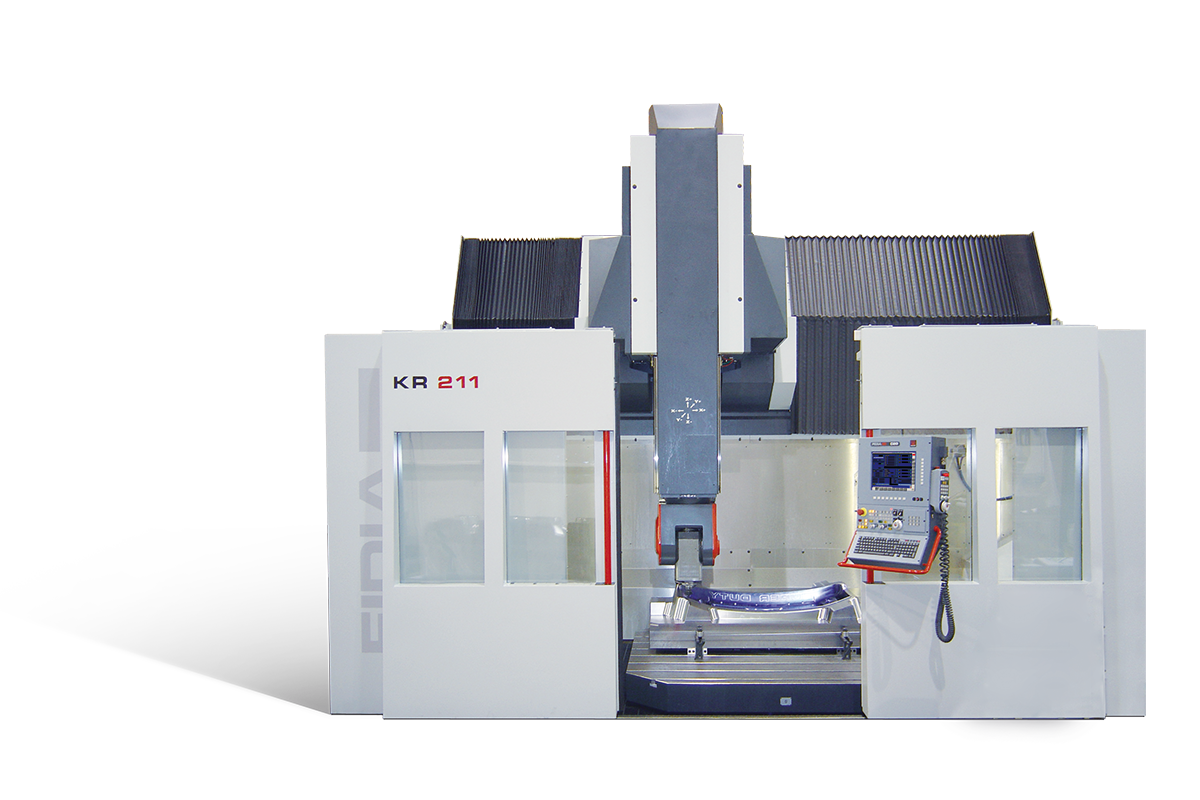

KR RANGE

Structure with rotary table

Based upon a K-line machine, it is characterized by the integration of the 5 axes head with a continuous rotary table. The rotary table is sized according to the machine application, and allows for the machining of workpieces of more than 2.000 mm as diameter.