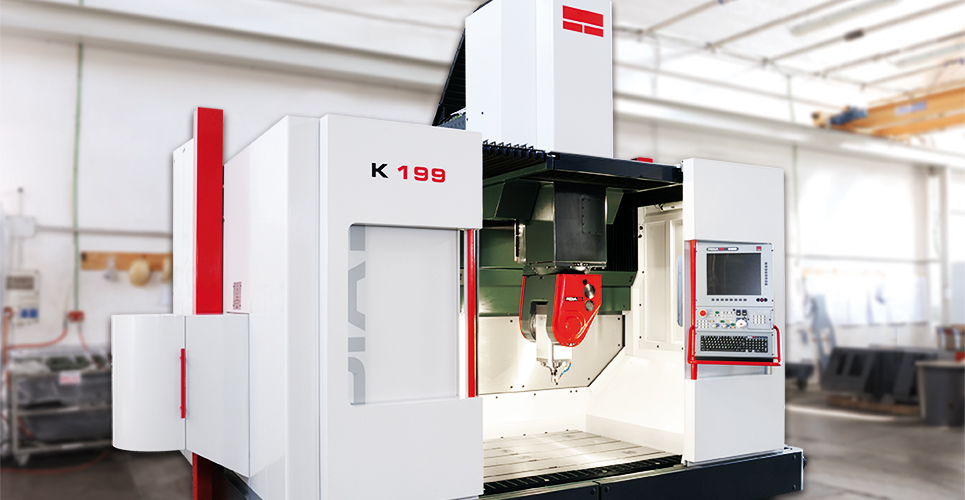

K199

The K199 is the smallest machine in the K Series. It uses motors with ball screws for linear axis movement.

The screws are mounted on cooled supports providing an excellent guarantee against thermal drift.

K Series' brochure

General catalog KDGH

Features and layout

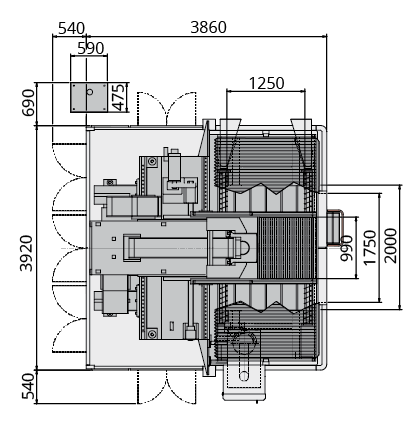

| Linear axes travel | X | Y | Z |

| (mm) | 1650 (65”) | 750 (30”) | 850 (33”) |

| Axes speed | |||

| (m/min) | 30 (1181 ipm) | ||

| Milling Spindles | bi-rotary continuous/indexed | ||

| Speed (1/min) | 24000 | ||

| Max power (kW) | 55 | ||

| Toolholder | HSK63A | ||

| Work-piece table: | |||

| Dimensions | 2000 x 1250 mm (79” x 49”) | ||

| T-Slots | n° 5 - pitch 250 mm (10”) | ||

| Loading capacity | 12000 kg (26455 lbs) | ||

(*) +150 mm rotating the C axis with vertical spindle

Milling head assembled on K199

M5A/55

The M5A/55 continuous bi-rotary head is ideal for medium-size or large milling machines that perform the complete machining cycle, from roughing out to finishing, where higher torque and power are required in HSC applications.