Y2K

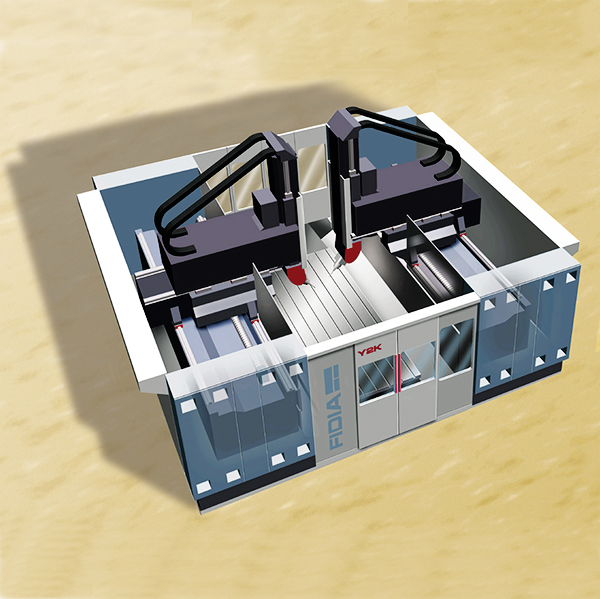

Fidia’s experience as a unique supplier of global solutions has made this special configuration possible. It consists in the combination of two basic systems sharing the same work-piece table. Productivity is therefore doubled compared to a traditional portal machine.

Furthermore, the extremely flexible software gives excellent results when machining dies, large dimensioned single components or when directly approaching separate pieces. This is achieved thanks to the fact that the 2 NCs allow for independent and different milling part-programmes ensuring total safety for each machine’s working area.

A tool measuring system in common with both sections and a piece alignment device grant a correct synchronism between the machines allowing for a perfect and constant machining of parts

Features Y2K

| Y2K4 | Y2K7 | Y2K10 | |

| Linear axis travel | |||

| X(*) | 4200 mm (165”) | 7500 mm (295”) | 10800 mm (425”) |

| Y(*) | 2200 mm (87”) | ||

| Z | 1000/1400 mm (39”/55”) | ||

| Linear axis speed | X | Y | Z |

| 50 m/min (1968 ipm) | 40 m/min (1575 ipm) | 30 m/min (1181 ipm) | |

| Positioning accuracy | |||

| X | ± 0,0075 mm (±.0003”) | ± 0,010 mm (±.0004“) | ± 0,0125 mm (±.0005“) |

| Y Z | ±0,005 ±0,004 mm (±.0002” ±.00015”) | ||

| Work-piece table: | |||

| Dimensions | 5000 x 2200 mm (197” x 87”) | 7500 x 2200 mm (295” x 87”) | 10000 x 2200 mm (394” x 87”) |

| T-Slots | n° 9 pitch 250 mm (10”) | ||

| Loading capacity | 9000 kg/m2 (1843 lbs/ft2) | ||

| Tool magazine | |||

| No of positions | 2 x 42 - 2 x 84 | ||

| Weight | |||

| 64000 kg (13108 lbs) | 84000 kg (185000 lbs) | 100000 kg (220000 lbs) |

|

(*) +150 mm (6”) rotating the C axis with vertical spindle