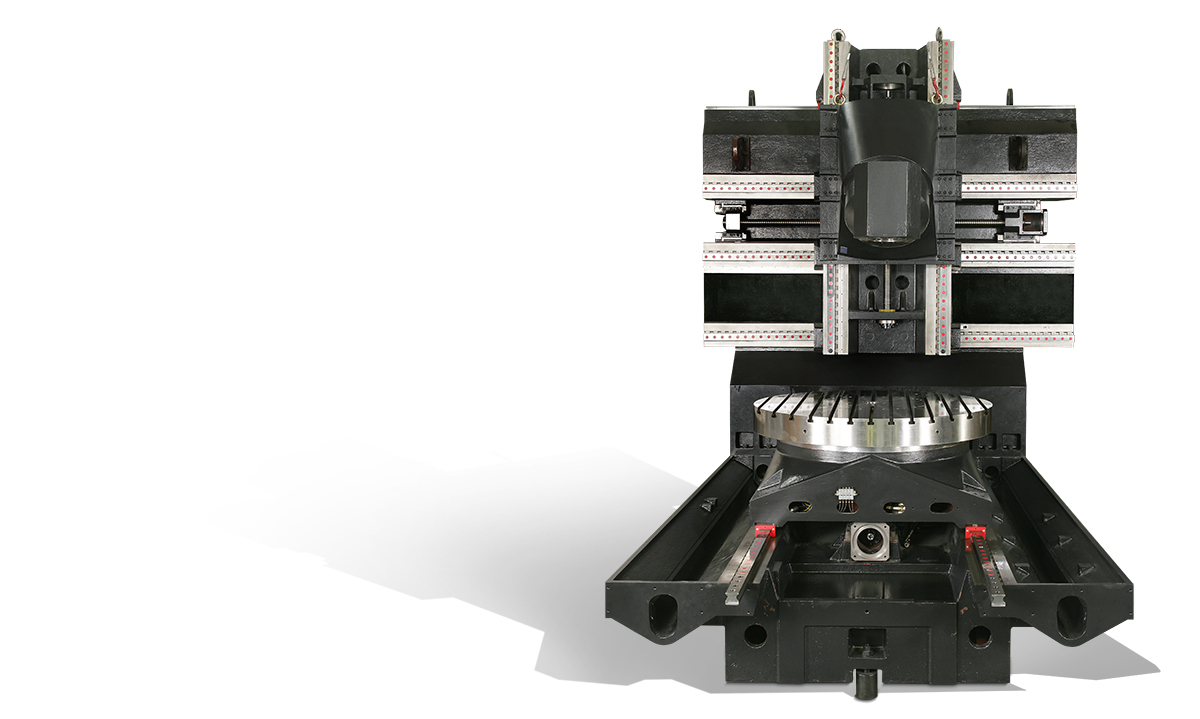

UHE 1000/1600

3 separate castings morphology grant outstanding accuracy and high performances in any milling condition. 5-axis interpolation in combination with the rotary table allow 5-side machining of complex components, in a single, easy set-up.

UHE High-Speed Machining Centers have application in different sectors:

Aerospace

- structural parts

- landing gears

- turbine discs

- turbine blades

- impellers

- composite routing

Automotive

- plastic injection moulds

- stamping dies

- forging dies

- die-casting dies

- tire moulds and models

- prototyping and styling models

General Mechanical

- energy power components

- machine tool

- transmission gears

- complex shaped parts

UHE 1000

UHE have the most efficient structure for multi-sided high performance machining, increase of productivity, flexibility and repeatability.

Main characteristics:

- 1000 x 800 x 700 mm travels on X/Y/Z axis

- 1000 x 800 mm rotary table, 1500 kg payload

- 0.001° swiveling head

- Torque motor driven B axis on swiveling head and Worm gear driven C

axis rotary table - Spindle: 18000 rpm HSK63A (with 26/32 kW 124/154 Nm) or 24.000 rpm HSK63A (with 21/27 kW 85/116 Nm)

- Simultaneous 5 axis machining

- Great flexibility to manufacture individual parts

- Maximum stability thanks to balanced load distribution

- Highest machine precision and repeatability is achieved reducing the axis overlapping

- Sliding front and side doors with a super wide opening for any easy load-download of parts.

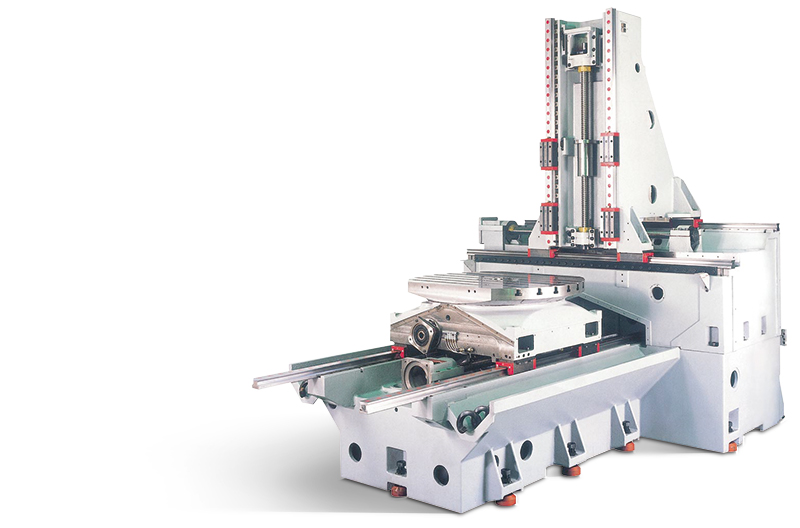

High rigid casting frame

Rigid casting frame

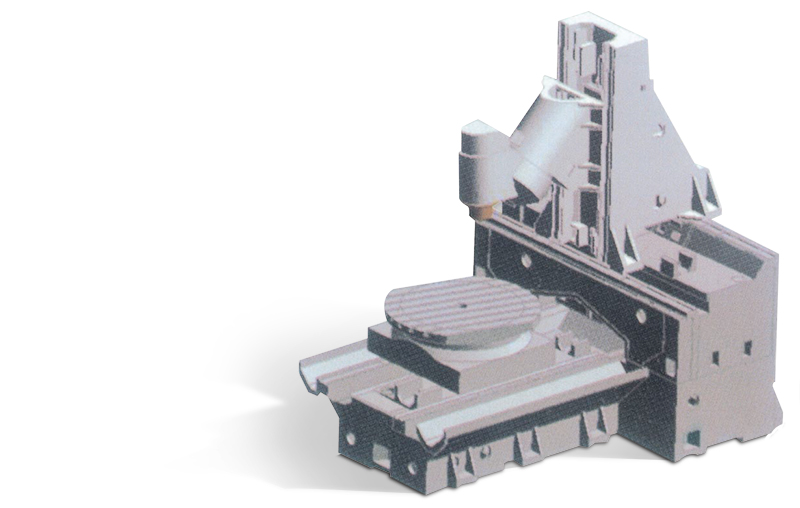

The most advanced FEM technology has been utilized to design an extremely rigid casting frame. The machine is composed by 3 separate casting parts: machine bed, X axis column and spindle headstock.

Outstanding Accuracy

High-end standard equipment guarantee both outstanding accuracy and high performances of the machine. High precision linear scales on 3 linear axis X Y & Z. High precision direct rotary encoders for the B & C axis.

Axes technology

Ball screws

High precision Φ50mm ballscrews on 3 axis are directly coupled to powerful AC servo motors to provide the utmost results in high speed cutting with best finishing quality.

Roller Guideways

Highly rigid - heavy duty roller type linear guideways, provide low starting inertia, low friction, high acceleration rates and optimize machine response in high speed cutting.

Ladder bed

The one piece casting ladder bed has been designed to increase column resistance and rigidity.

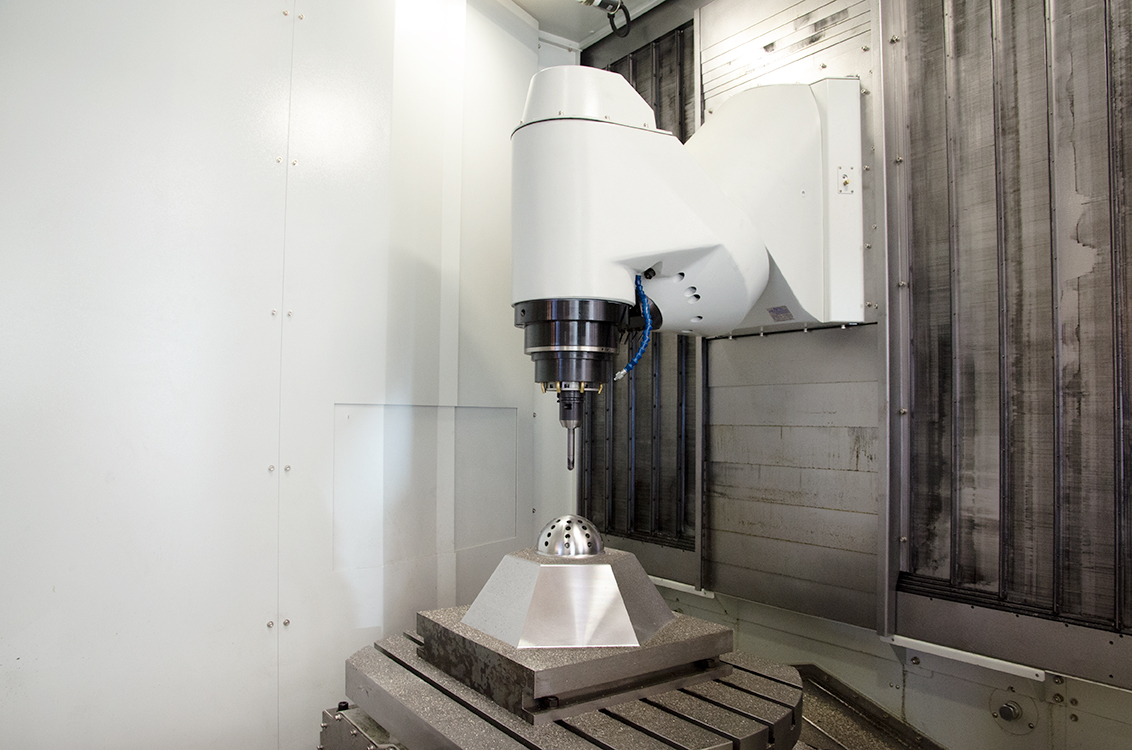

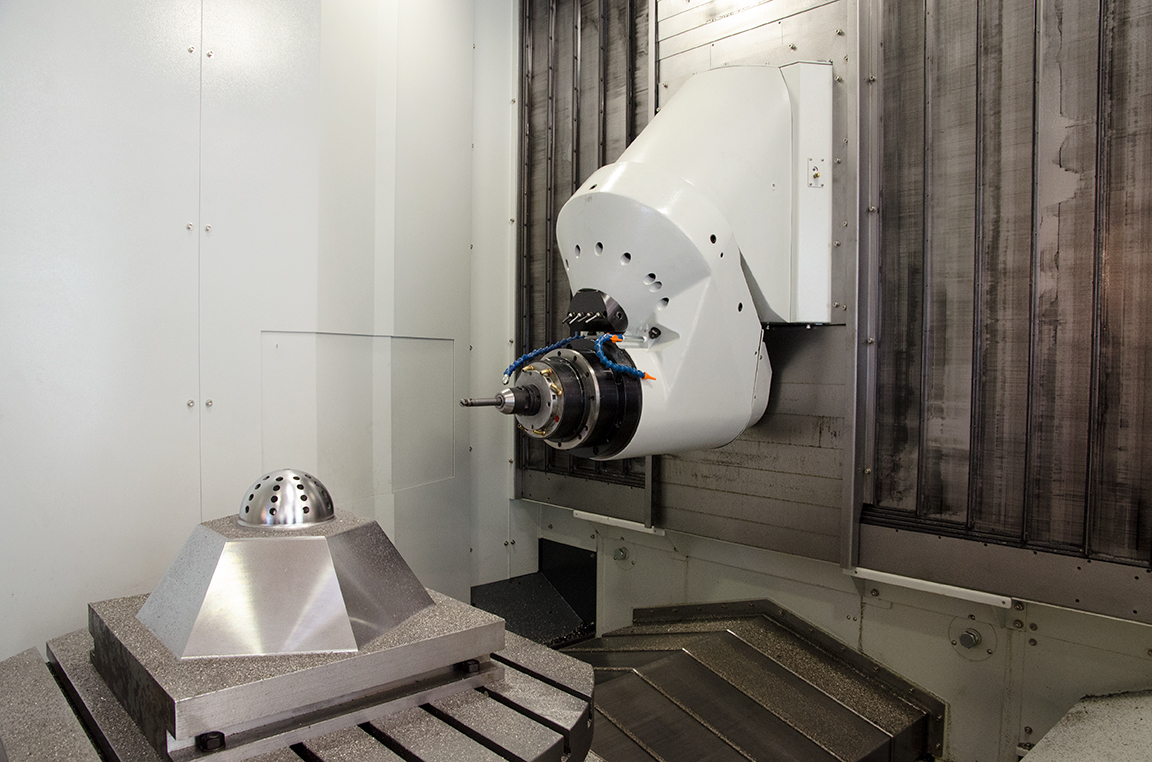

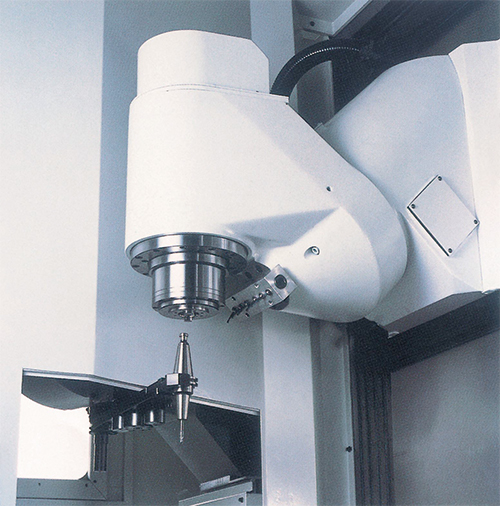

B Axis Innovative Swiveling Head

The latest technology torque motor manages the B axis continuous swivel milling head and guarantees maximum dynamic and linearity: the absence of traditional mechanical transmission allows much higher quality of surface finishing. The reading system with a direct angular encoder, grants precision and reliability. Suitable clamping torque is grant by an hydraulic brake system.

The fully automatic 0.001 degrees indexing from vertical to horizontal positions gives the operator all the flexibility for multi-sided machining without re-setting the workpiece. Moreover, 5 axis machining is performed by the rotary table in combination with the swiveling head

C Axis durable rotary Table

The table incorporates a standard 1000 x 800mm clamping plate and is driven by AC Servomotor. It can be indexed 0.001° by an high precision worm gear and high precision direct rotary encoder. Clamping torque over 4.000 Nm is grant by an hydraulic brake system.

Wide Throat Distance

The very wide distance, 700mm between spindle center and X axis slideway cover, gives the operator a great convenience for different workpiece setup.

Automatic Tool Changer

40 positions chain type with a double swing arm ATC is a standard.

Optional is a 52 position version.

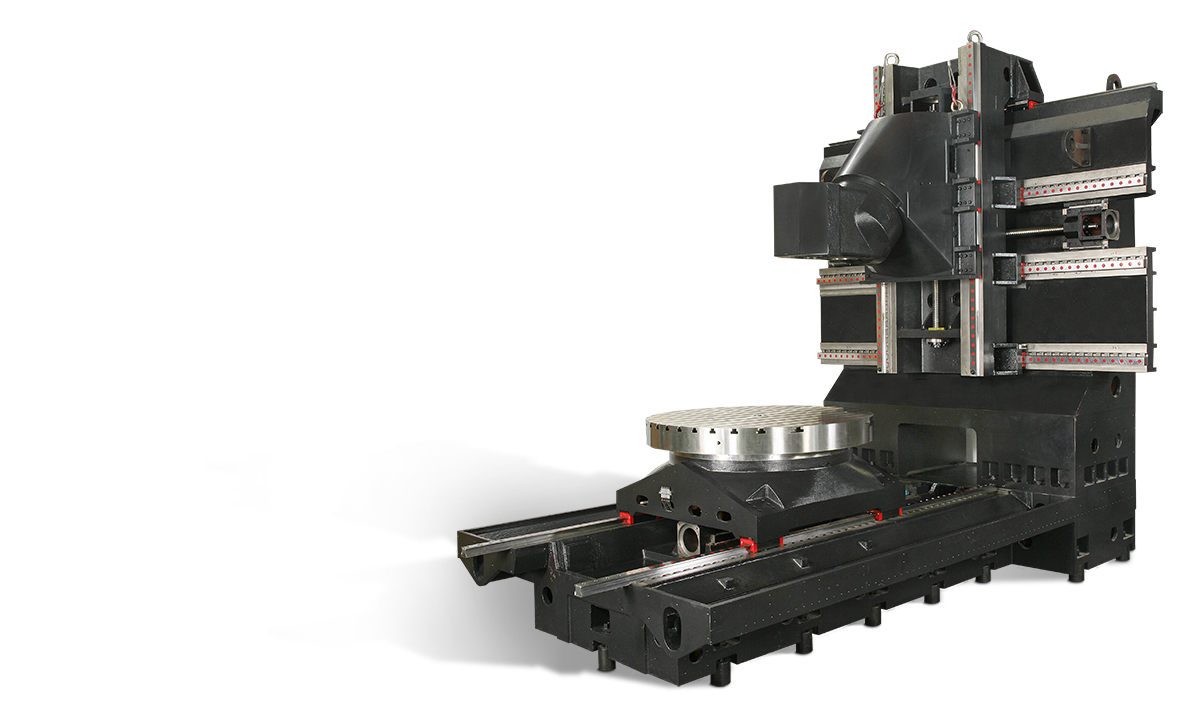

UHE 1600

Latest innovation in combination of both bridge type machine and travelling column type machine for heavy duty 5 axis simultaneus machining.

Main characteristics:

- 1620 x 1260 x 1050 mm travels on X/Y/Z

- Ø 1320 mm torque motor rotary table, with 4000 kg work load

- 0.001° swiveling head with torque motor

- Standard 8000 Rpm HSK-A100 /BT#50- 36/45 kW 340/418 Nm with Ø 100mm Ceramic bearings motor spindle (Optional 15.000 Rpm HSK-A-100 20/26kW 290/317 Nm)

- Exclusive 4 linear guideways system on X axis grants maximum rigidity and allows heavy duty cutting operations

Rigid casting frame

The most advanced FEM technology has been utilized to designed an extremely rigid casting frame.

Roller guideways

Highly rigid - heavy duty roller type linear guideways, provide low starting inertia, low friction, high acceleration rates and optimize machine rigidity and dynamics.

Ball screws

High precision ballscrews on 3 axis are directly coupled to powerful AC servo motors to provide the utmost results in high speed cutting with best finishing quality.

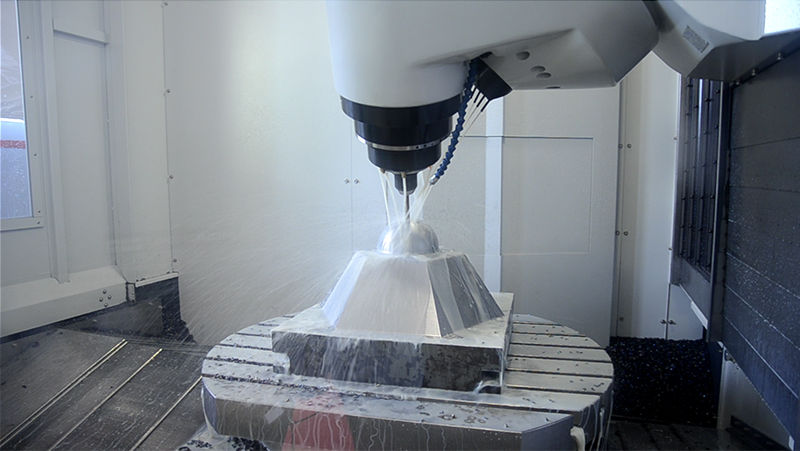

High speed milling

The extreme rigidity and precision of the machine allow high speed milling machining. The Fidia CNC and Fidia Digital Drives provide the best milling results on the machine tool, optimizing speed accuracy and best quality surface, by using advanced feed and acceleration smooth dynamics algorithms, thus preserving mechanical component life.

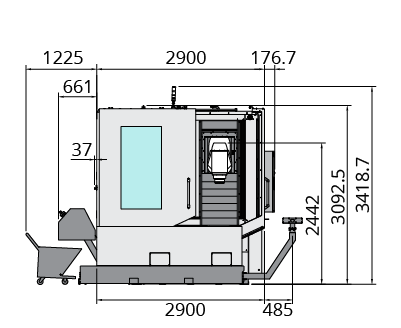

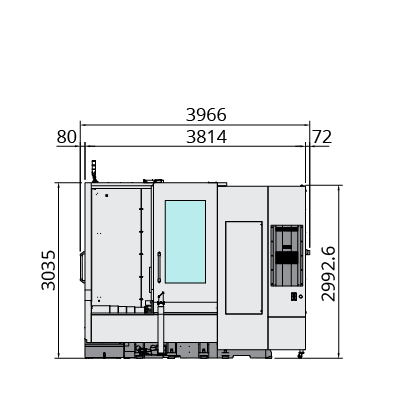

Technical data and layout

| Axis speed | X | Y | Z |

| UHE 1000/1600 | 24 m/min (945 ipm) | ||

| Linear axis travel | X | Y | Z |

| UHE 1000/1600 | 1000/1620 mm (39.7/63.7”) | 800/1260 mm (31.4/49.6”) | 700/1050 mm (27.5/41.3”) |

| Rotary axis | Table | Max load | Milling head |

| UHE 1000 | 1000 x 800 mm (39.7”x 31.4”) | 1500 kg | 0°-180° pitch 0.001° |

| UHE 1600 | Ø 1400 mm | 4000 kg | |

| Milling spindles | Speed (rpm) | Power/torque (max) | Toolholder |

| UHE 1000 | 18.000 (opt 24.000) | 32 kW / 154 Nm | HSK63A |

| UHE 1600 | 8.000 (opt 15.000) | 45 kW / 418 Nm | HSK100A |