Customized automation

PRC: the basic solution

The Fidia CNC provides for a sequence of operations that can be stored in a “Procedure” (PRC) and then executed automatically.

Using an editor, the operator writes in a file a sequence of instructions in PRC language, each of which defines the value of a parameter or the execution of a command on the CNC.

Specific instructions can also increase parameter values, execute cycles or execute conditional jumps depending on the value of parameters.

Once the Procedure is started, the CNC will execute the operations indicated by each instruction as if they had been entered by the operator from the CNC keyboard. This technique simplifies repetitive machining operations, improves operating safety and enables a series of unmanned machining operations to be performed.

PRX: for complex processes

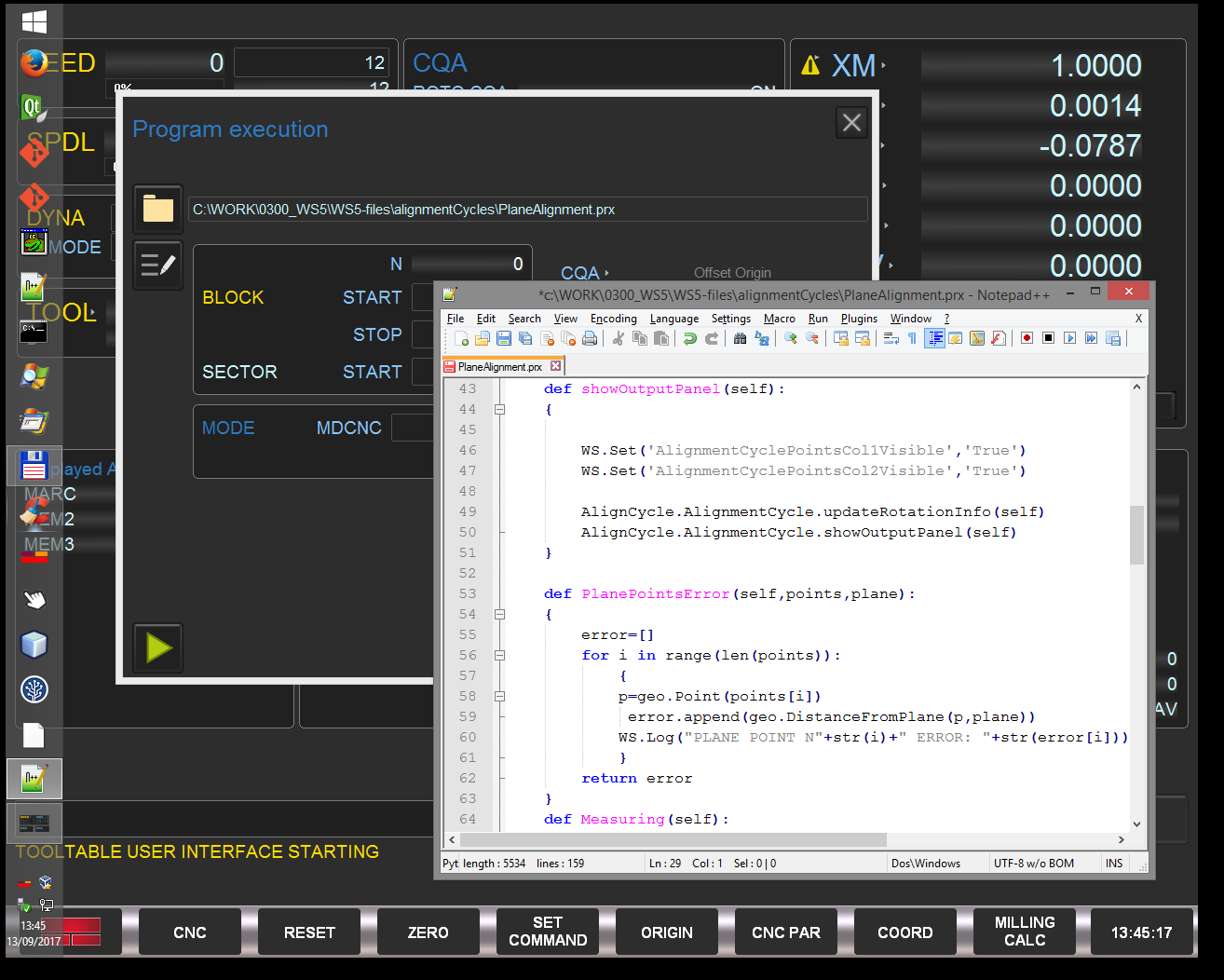

Ever more demanding automation requirements have led Fidia to develop a new language to define complex machining processes. This language, called PRX, uses a similar syntax to the Python programming language; all its functions are accessible, as well as the commands for the operations to be executed on the numerical control. The user can also access standard libraries and insert customized modules. The PRX language is interpreted and does not need to be compiled, ensuring portability to future Fidia CNC software versions.

Advantages of PRX

In addition to all the functions offered by PRC procedures, the PRX language allows for:

- Accessing data available on the control

- Performing complex calculations

- Executing conditional jumps depending on parameter values, data obtained by the CNC or received from connected external devices

- Interaction with the operator, for example stopping execution while awaiting consent or data entry

- Exchanging data with external devices, with another control or a PC

- Producing reports

- Updating databases with data relating to calculations, measurements and machining.

Owing to the wide range of functions available, PRX procedures have a variety of applications - from producing a report to performing geometrical calculations, or from collecting data for statistical purposes to accessing information stored on a PC.

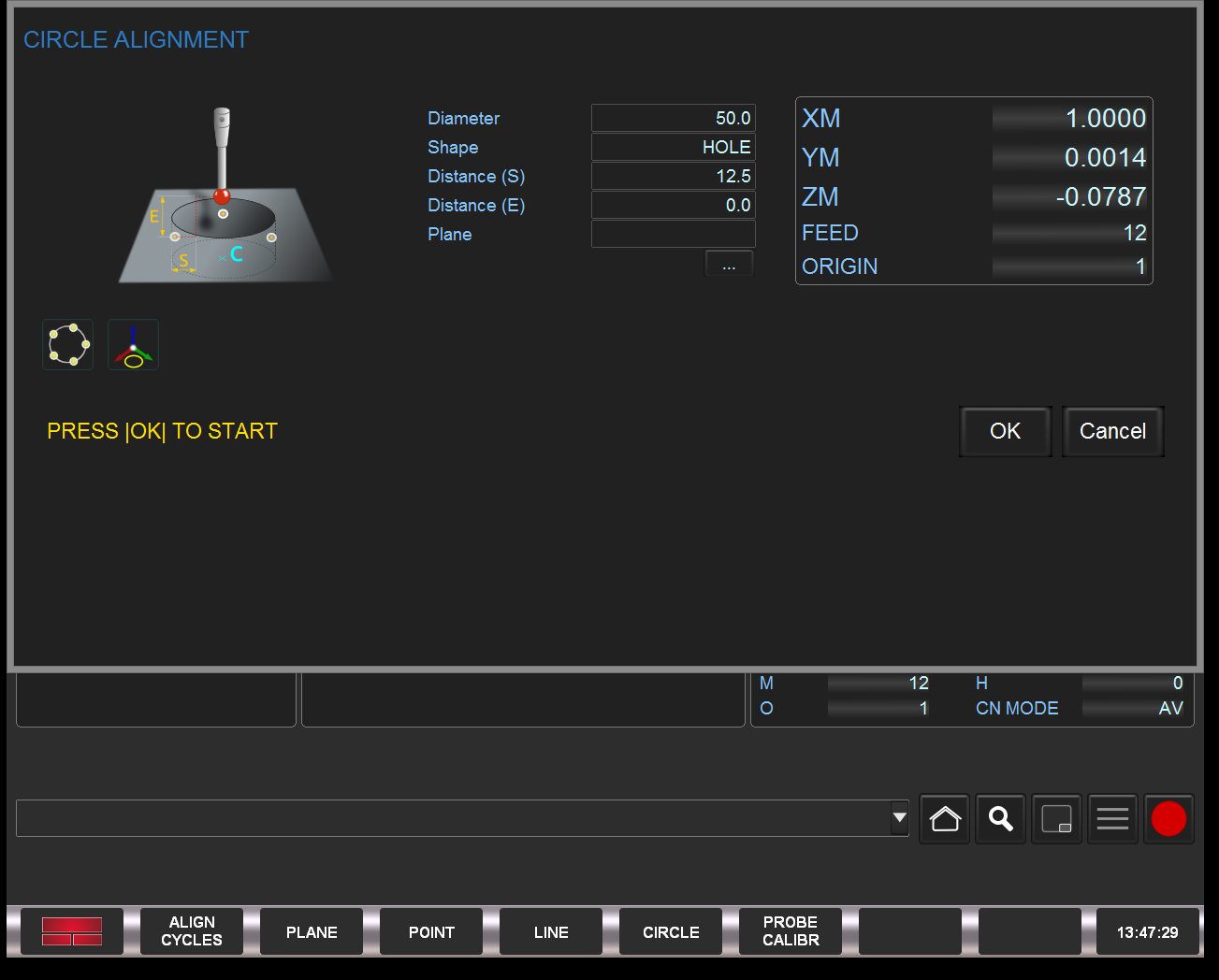

Cases that are of particular interest concern the interaction between measurement results (made by digital probes on the machine) and part programs. For example, when machining standard parts you can:

- perform a measurement cycle on the rough part

- calculate any misalignment of the rough part

- calculate the rotation and translation parameters in order to align the machining path with the rough part

- load these parameters into the CNC

- execute the machining

The whole process is done without any intervention on the part of the operator. Alternatively, the PRX procedure can stop execution while awaiting data or the operator’s consent.

Procedures in the PRX language can be produced by the Client directly at the machine or by the CAD/CAM department. Fidia is available to provide assistance or produce PRX procedures in accordance with the Client’s specifications.