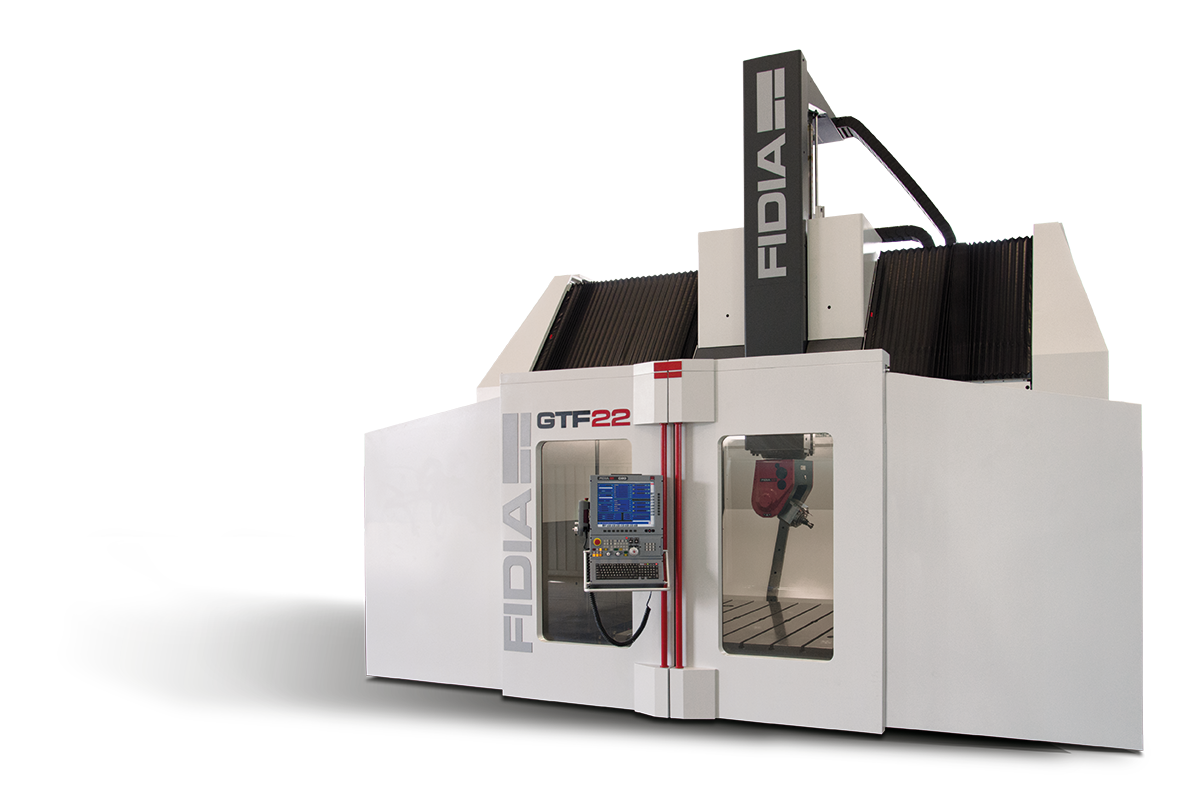

GTF Line

Gantry Type high speed milling machines

Modularity

The upper Gantry GTF line is characterized by great versatility. Thanks to its modular structure, and taking advantage of a combination of components conveniently selected according to weight, stiffness and cost requirements, the GTF range becomes an ideal solution to fulfill all Customers’ demands.

Performances

The sizing of its structures in accordance with the thermo-symmetry concept,perfectly matches with the extreme dynamic linear axes. Rack & pinions driven by double motors and variable preload grant for total absence of backlash.

Fidia technology inside

The FIDIA integrated technology system, including both drives, and numerical control, offers the most complete and performing equipment, granting the customer with both quality and reliability of one-single-source supplier.

Continuous and indexed bi-rotary heads

With any of FIDIA’s heads, the A and C axes performs high dynamic continuous interpolation as well as the 3+2 positioning mode. When using 5 axes machining, the rotative axes (A,C or both) can be stiffly clamped by means of powerful hydraulic brakes, exploiting the maximum torque of the spindle. The axes cinematic chain is provided with lifetime automatic backlash recovery and is able to perform 0.001° resolution positioning.

Applications

GTF machines offer a full range of models with a wide and modular work envelope. Thanks to the wide choice of Ram and milling heads solution, GTF always find the best fitting application in various fields:

- Automotive

- Aerospace

- General Machining

Aerospace

High accuracy and efficiency in 5 axis machining is essential for operating on many types of aeronautical and aerospace structural components. GTF has specifically designed solutions to afford machining of each material utilized in aerospace: aluminum, titanium, composite materials require chip conveying systems with filtering and protection for both the environment and the machine itself. In the GTF family there is always the right model to fit in the best price/ performance ratio.

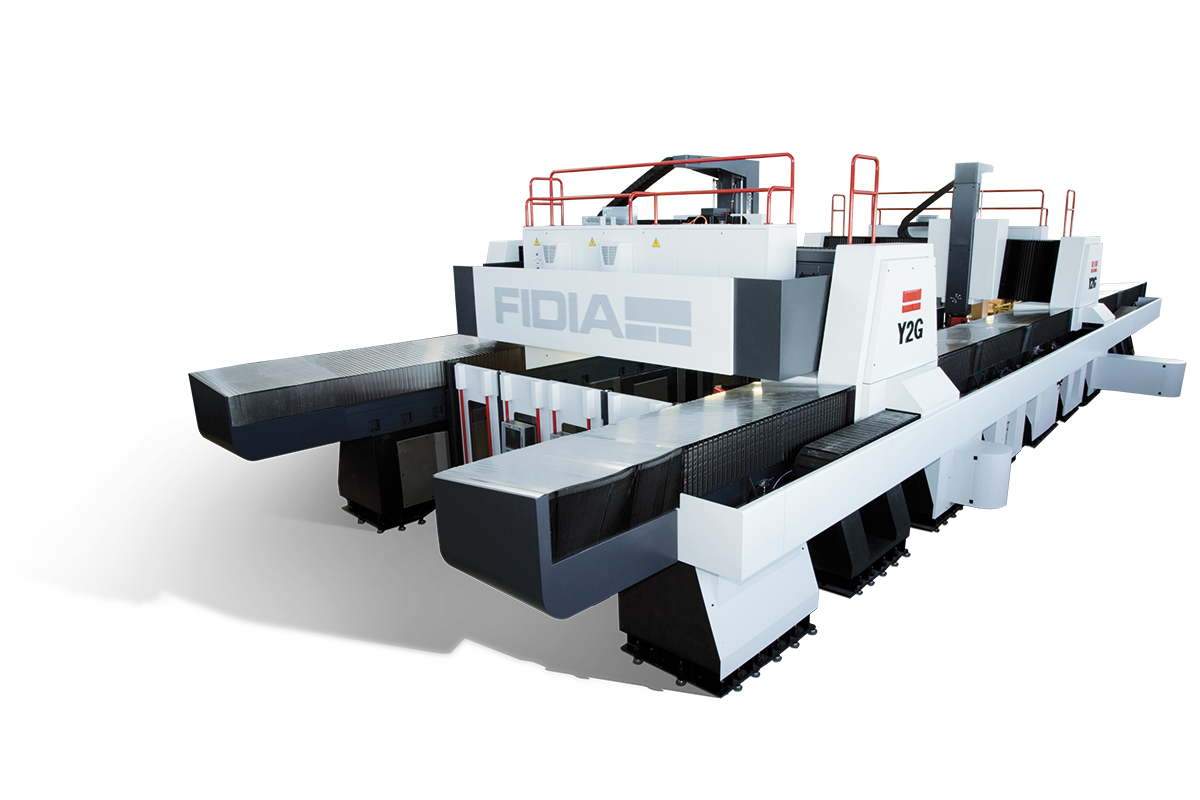

General Machining

Thanks to the modular design it is now possible to utilize FIDIA technology to produce large size mechanical components. A typical example is the wind-turbine power generator, from the blade forming mold to the gear and its casing. Energy as well as Naval or Rail industries sometimes require very accurate machining cases, which can only be accomplished by specifically designed machines. The M5H head version offers the most advantageous solution in terms of stock removal rate combined with high quality and precision. The addition of tables and accessories for turning further extends the application field of these machines.

Automotive

Stamping dies

The automotive industry requires powerful and highly accurate machines to mill cast-iron and steel dies from the roughing operation to the final superfinishing. Thanks to GTF’s fixed table-upper gantry configuration, manual polishing can be mostly avoided and all operations can be done with a single set up of the workpiece.

The most difficult areas of the component are attained by an appropriate choice of heads and milling accessories.

Plastic injection and die-casting

These type of molds require precision in details and high surface quality. The unique design of the bi-rotary head of Fidia reduces the tool length, avoiding vibration and thus improving the surface quality. The use of direct encoders and a complete thermal control of structures grant for the highest positioning accuracy during the long milling cycle time required by these complex applications.

Prototyping and styling

The machining of full-scale models for automotive industry, the construction of prototyping molds and quality control gauges match perfectly with the GTF working envelope and technical solutions.

The XYZ axes high dynamic accuracy and the compact size of M5A & M5C heads bring GTF to an upper performance level, defying all competition. A range of suitable dust suction equipment is available in order to work all type of “light materials” as resin, carbon fiber, clay, etc... This equipment guarantees a high efficiency of suction performance and a total protection of the work environment.