New Numerical Control C40

The leading control in the Fidia range, the C40 offers specific solutions, developed to guarantee high level performance for high speed machining on 5 or more axes. The C40 control is ideally suited for the milling of aeronautical components and moulds & dies, where high feeds are required together with high precision. The RTCP function, that simplifies the use of 5-axis machines, and the Velocity 5 technology, combining high speed with excellent quality, take advantage of the processing power of the C40.

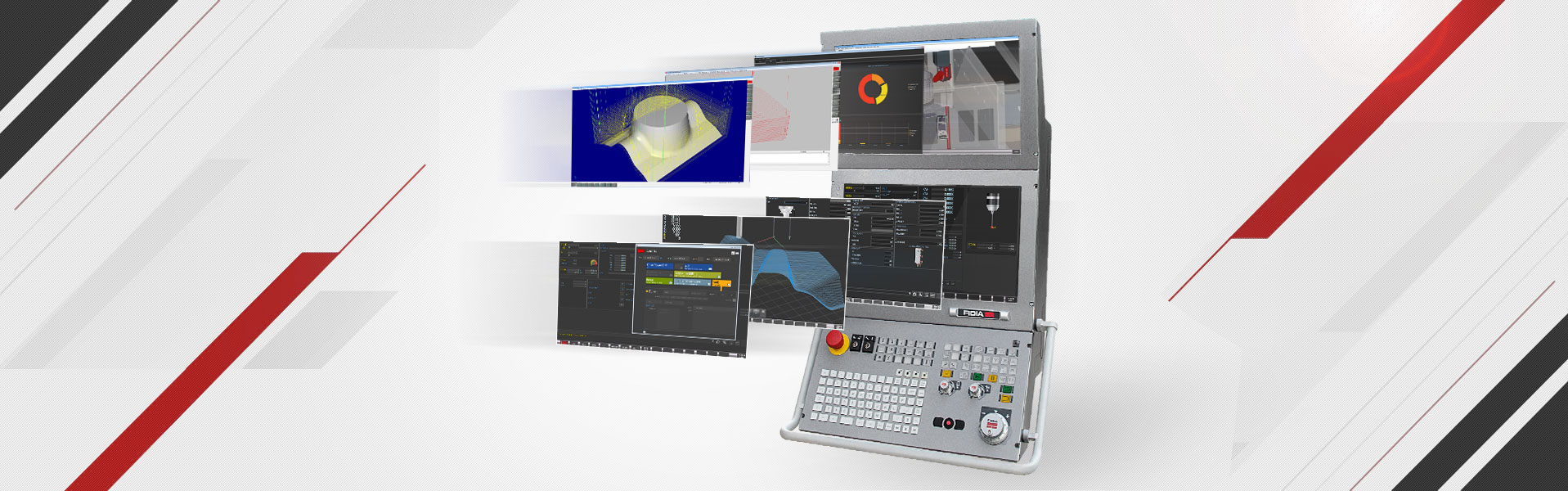

The dual monitor configuration allows for full and simultaneous control of the machine tool parameters and user applications. For example, the machine tool data can be displayed at the same time as the ViMill anti-collision software screen or images from machinemounted cameras, or also images from other display or simulation software.

Fidia C40 performs all different kinds of machining in the most effective way, thanks to the wide range of available functions. Machine tool operators, as well as CAM engineers, can easily assess the best approach to each machining function, supported by a complete set of CNC features that allow the best flexibility and efficiency under any condition.

Numerical control functions and options

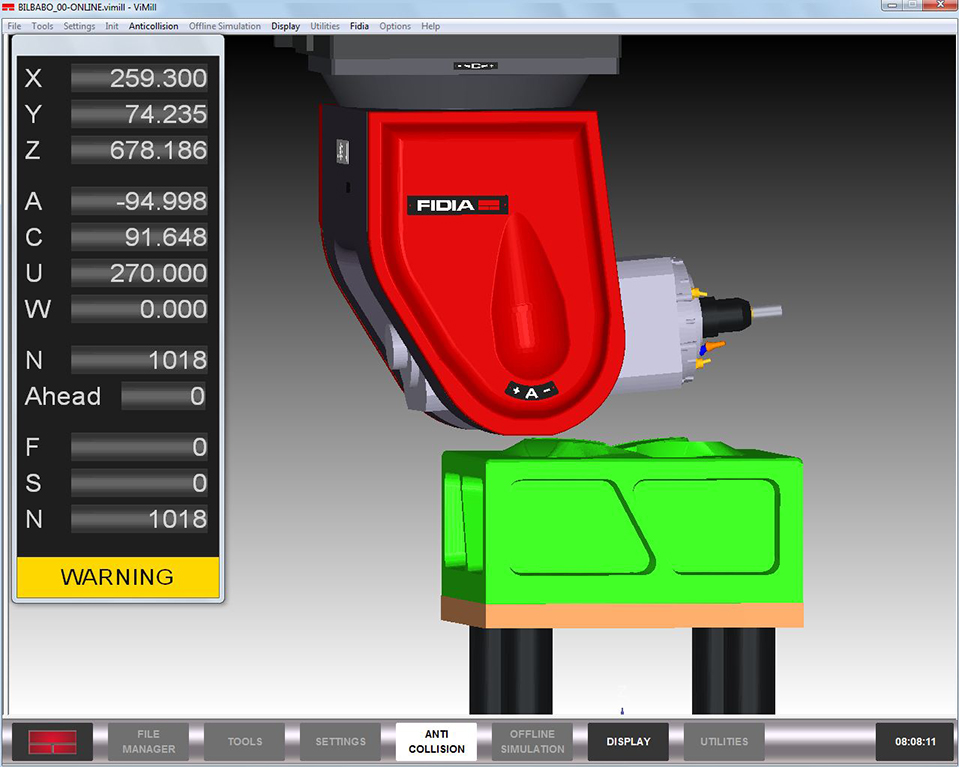

ViMill®

Fidia ViMill anti-collision software finds an ideal configuration in the C40 numerical control. ViMill ensures the total safety of machining operations, continuously monitoring all machine tool movements, and locking the axes in the event of a possible collision between the tool, machine and workpiece, both in program and manual mode.

HMS™

The HMS™ bi-rotary head calibration system, combined with the RTCP function, is a unique and winning formula in 5-axis milling technology. The system obtains precise positioning accuracy of the tool tip by means of a fully automated calibration procedure that is independent of any mechanical or electronic error in order to ensure maximum machining accuracy.

Read more

Velocity Five™

Through an optimum dynamic management of the machining parameters, the innovative V5 tool path control technology enables accurate, high quality surfaces to be obtained, both in roughing out and finishing, while guaranteeing high feeds with a subsequent reduction in machining time

Read more