HMS, the greatest accuracy on 5-axis machining

For the greatest accuracy on 5-axis machining

HMS is a device designed to measure and to compensate geometrical error on continuous or indexed bi-rotary heads, and on roto-tilting tables.

The system works in conjunction with the Fidia CNC.

HMS improves the accuracy and quality of 5-axis milling, without the need for complex service interventions by specialist engineers.

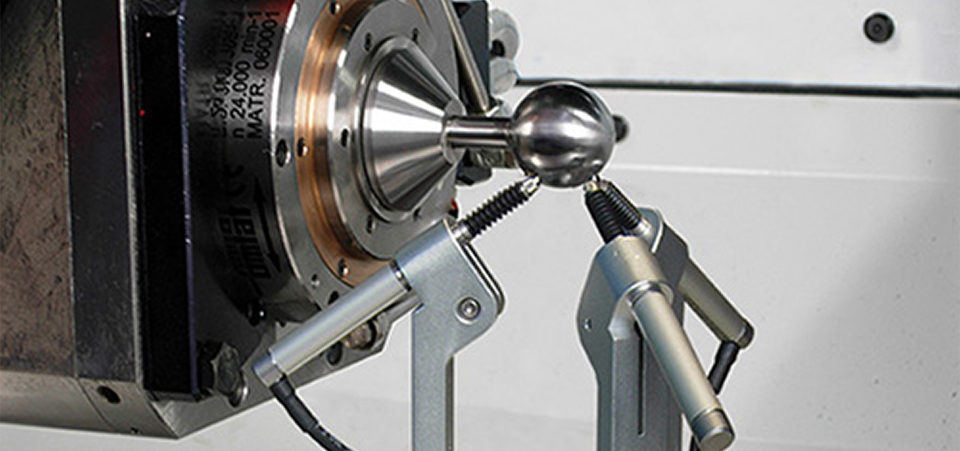

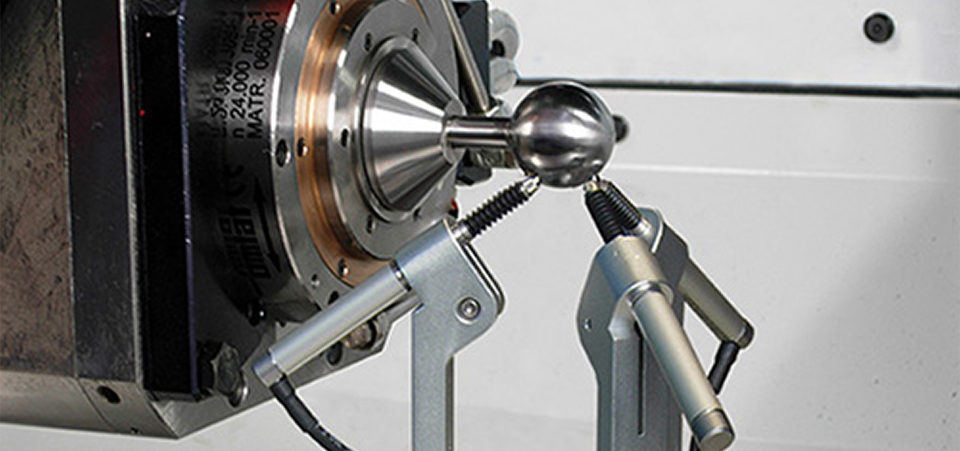

The system consists of a support with three sensors that is attached to the machine table, and a software management module; two high precision spherical tip bars are supplied with the instrument.

The system consists of a support with three sensors that is attached to the machine table, and a software management module; two high precision spherical tip bars are supplied with the instrument.

To execute the measuring and compensation cycle, the operator has to:

- fit a high precision bar on the machine spindle

- move the machine tool axes to bring the bar into contact with the three sensors

- start the automatic measuring and compensation cycle.

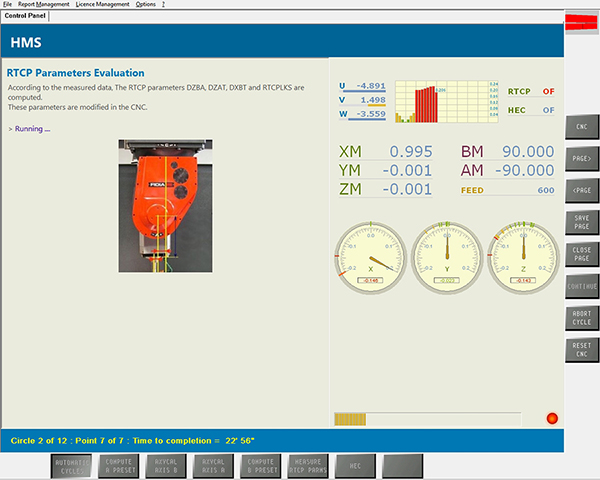

During the measuring cycle, the HMS software detects any geometrical error of the head, or of the roto-tilting table, calculates the parameters in order to compensate the error and activates them automatically.

Easy to install and to use, HMS does not require any particular expertise and can be used by the machine tool operator

HMS is a high precision instrument that provides a valid alternative to traditional checking methods; the system has many advantages:

HMS is a high precision instrument that provides a valid alternative to traditional checking methods; the system has many advantages:

- simple and immediate application

- a drastic reduction in checking time, just one hour for the full cycle

- error measurement over a wide range of positions, not just in orthogonal positions

- correction of RTCP parameters according to the actual measurements

- automatic uploading of compensation parameters to the CNC

- creation of a history of error, allowing analysis of error evolution

With its magnetic base the HMS device is easily fitted on the machine table and does not need any alignment; the management software guides the operator by means of a simple and intuitive user interface.

HMS improves the accuracy and quality of 5-axis milling

The HMS measuring and compensation system is a winning and unique solution for 5-axis milling technology, offering significant advantages in terms of accuracy and machining quality.

At the end of the cycle, the software automatically uploads the compensation parameters to the Fidia CNC and provides a report on any detected errors, also shown in graphic format for an easier reading of the data. These reports are useful for checking the geometrical inaccuracies of the head, or of the roto-tilting table, and for planning any maintenance work required on the mechanical parts.

Easy to install and to use, HMS does not require any particular expertise and can be used by the machine tool operator. This means that geometry checks can be performed whenever necessary, avoiding maintenance interventions and reducing machine tool downtime.

The HMS device and its applications have been granted Patent:

- no. EP1549459A2 in Europe

- no. US20050234671 in USA

- no. CN1688949A in China

Download the Brochure: