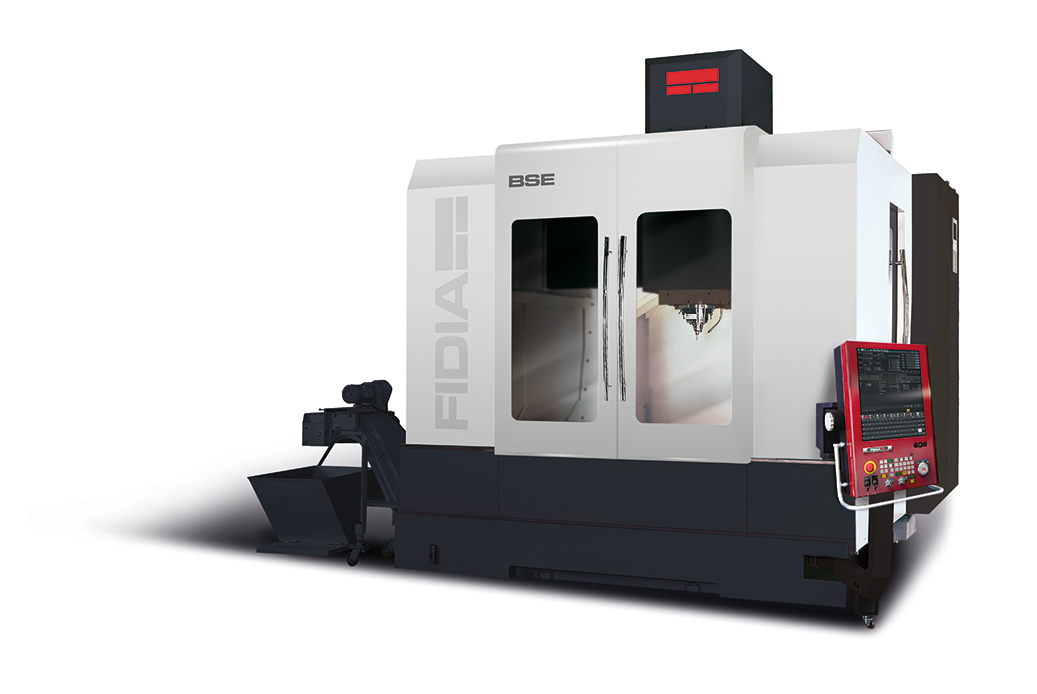

BSE

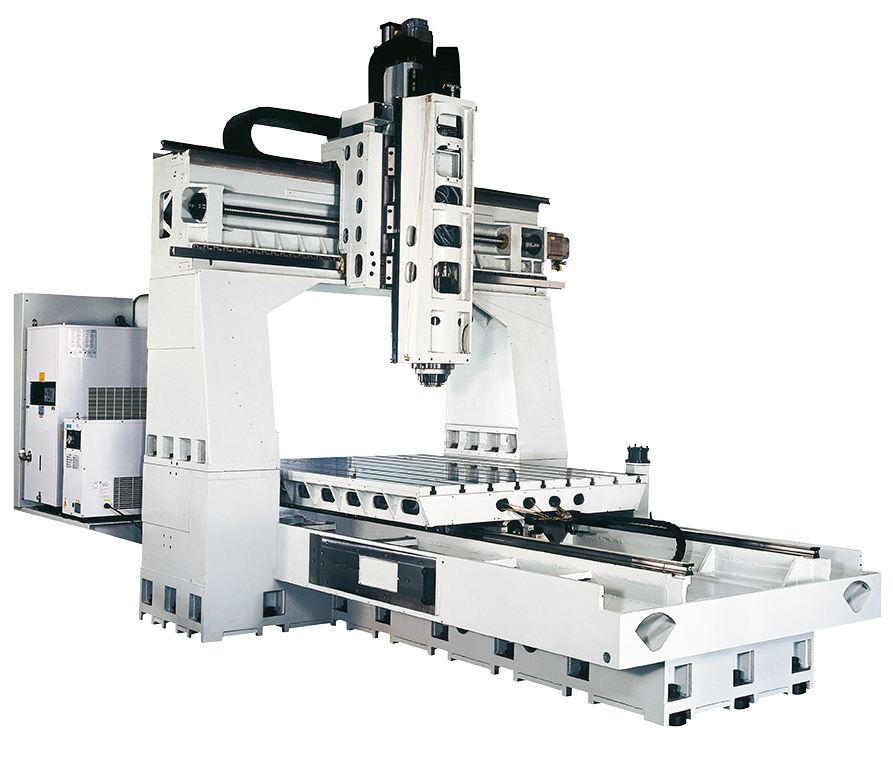

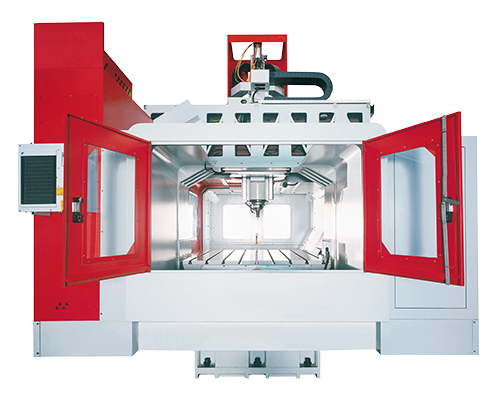

This line of machining centers is characterized by the moving table and fixed bridge type structure. High dynamics and machine accelerations, in addition to the use of electrospindles with high rates of rotations, makes this machine ideal whenever the high speed milling technology is required.

Features and technical specifications

BSE 1000

With High Rigidity, High precision and High Speed, the Fidia BSE represents the evolution in Mold&Die machining .

Spindle

BSE 1000 milling centres can be equipped with different spindles designed to satisfy the most advanced market requirements:

The 18.000 Rpm grease lubricated electrospindle allows high speed finishing and High Speed roughing when the 27 Kw/64.5 Nm is delivered.

Optionally, 24.000 Rpm is also available for the high quality finishing milling. Spindle is water cooled to control thermal effects.

Large Workpiece load & Traverse capacity:

- 1.100 x 600 x 500 mm travels on X/Y/Z

- 700 mm Distance betwwen Columns

- 1.220 x 600 mm Table size with 1.500 kg. work piece load.

- The wide distance 700mm between twin column, allows the most convenience mounting of medium workpiece, Þxture or rotary table etc.

High quality Þnishing Electrospindles:

Optionals 24.000 Rpm and 30.000 Rpm 27KW/64.5Nm .

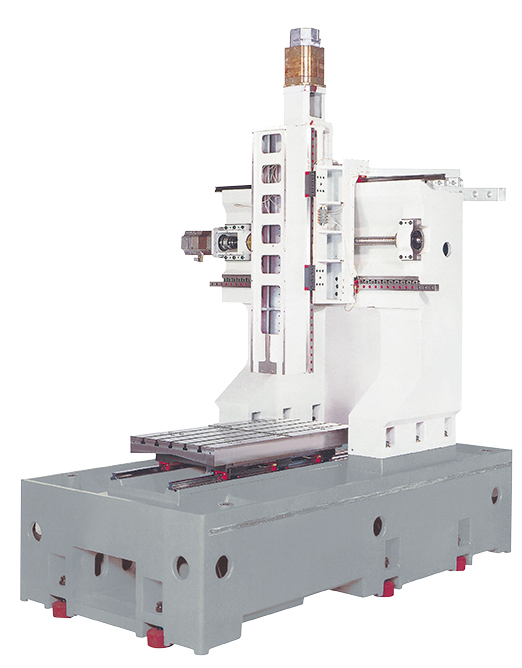

Rigid Bridge Column Type Construction

The characteristic twin bridge&column of BSE has been FEM calculated and it’s made of one piece Meehanite, highest quality casting. This design ensure maximum rigidity and performance in High Speed milling and reduces vibrations during heavy cutting operations. Thermal influences are minimized, due to the short distance between spindle axis and the portal structure as well as the permanent motor spindle cooling system. The machine bed is a casting athermally symmetrical designed.

User-Friendly & Ergonomic guarding design

The design of the guards allows for optimum viewing of the part being machined as well as ease of loading with a bridge crane. Totally enclosed guarding includes top side roof to keep all the chips, water and noise inside the machine and to have clean, quite and confortable enviroment also around the machine. The machine has been carefully to provide a reduction of overall floor space dimensions.

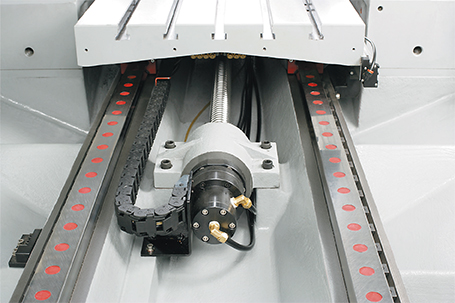

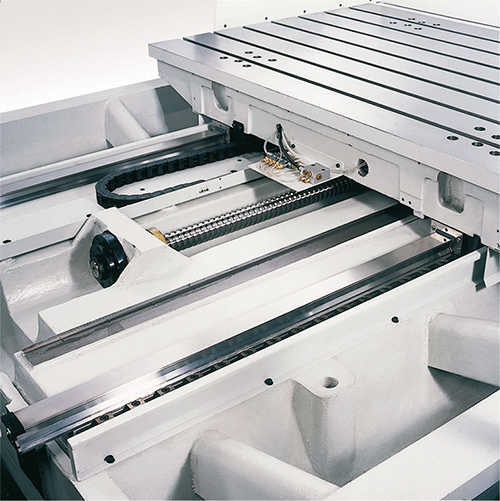

Ball screws

A ball screw central oil cooling system on X & Y axis draws the heat resulted by the very high speed transmission. Ball screws are cooled on both ends to minimize heat generated by high speed velocity thus maintaining position accuracy on axis. The mounting brackets on Z axis are integrated on the RAM castings to grant maximum rigidity.

Roller type Guideways

German high rigidity and heavy duty roller type linear motion guideways on 3 axis, provide low starting inertia, low friction and high acceleration rates. Servo motors and drives are optimized to ensure immediate & precise machine response necessary in high speed cutting, positioning and contouring.

Digital drives & Linear scales

The Fidia digital drives technology and the use of high resolution optical scales allow to optimize the machine tool dynamic behaviour and to achieve the maximum machining resolution and accuracy in high speed.

Fidia Look-Ahead V5

Advanced Path Control, Acceleration feed forward, Jerk control and automatic parametrization for high speed milling are some of the features of the Fidia Look-Ahead V5 installed on the BSE machines.

Guarding and Chip Conveyor

A screw chip auger under machine central bed delivers efficiently chips to the chain type chip conveyor & bucket. Excellent swarf and coolant disposal with continous bed cleaning leave the working area always clean. A viewing window located in the rear side of the machine guarding allows both to examine cutting conditions and easy maintenance.

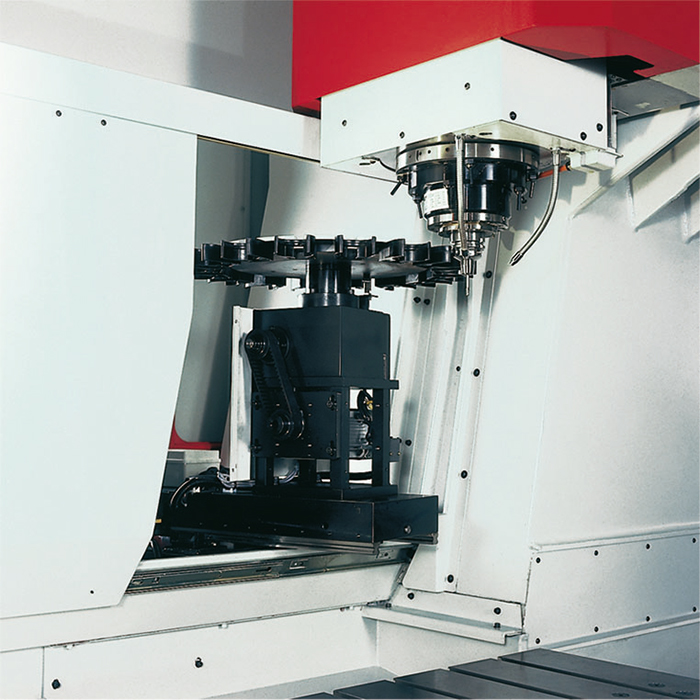

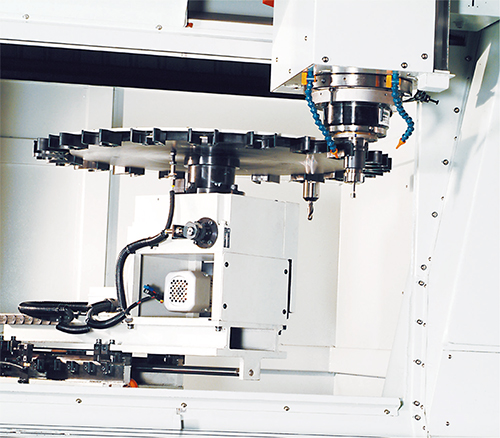

Automatic Tool Changer

Disk Type 16 station automatic tool changer installed as standard. Optionally, a 24/32 position tool changer and an automatic laser NC4 preset system can be supplied.

4 Axis Milling

When complex milling is required, a Rotary Table Φ 100 ~ 400 mm with tailstock can be supplied as an option. The rotary table can be positioned vertically or horizontally on the machine table.

GraÞte and Resin Milling

BSE Machines can be suitable for Grafite and Resin milling with balls screw protections and a powerful suction system: Optional Spindle up to 30.000 Rpm.

Features and technical specifications

BSE 1700

Large workpiece load & traverse capacity

- 1750 x 1000 x 750mm X/Y/Z travels, with 1750mm twin column distance.

- 1600 x 1000mm table size with up to 3000 kg work piece load.

Spindle with full power range: Powerfull built-in motor spindle 18000 Rpm HSK63 26/32 kW 124/154 Nm.

Automatic Tool Changer and Chip Conveyor

Automatic tool changer 24 positions, disk type, is standard. Optionally, a 32/40/60 position tool changer and an automatic laser NC4 preset system can be supplied. Chain type chip conveyor is standard.

Super wide & high rigid one piece casting twin columns

The very wide distance 1750mm between twin column, allow the most convenient mounting of large workpiece, fixtute etc. The high column is extemely useful for tall workpiece and those which requires long cutting tools.

Ridig double column bridge type construction

The twin column&bridge has been FEM designed is made of one piece Meehanite highest quality casting following the most advanced high speed machines concepts. The machine structure ensures rigidity and reduces vibrations coming from the tool during cutting.

High quality forged casting on saddle & ram

High quality special & tough forged casting FCD45 on saddle & ram to get the fastest feed response on Z axis movements.

Roller type Guideways

German high rigidity and heavy duty roller type linear motion guideways on 3 axis, provide low starting inertia, low friction and high acceleration rates. Servo motors and drives are optimized to ensure immediate & precise machine response necessary in high speed cutting, positioning and contouring.

Features and technical specifications

BSE 2200

Large workpiece load & traverse capacity

- 2200 x 1750 x 750mm X/Y/Z travels, with 1750mm twin column distance.

- 2100 x 1600mm table size with up to 6000 kg work piece load.

Spindle with full power range:

Powerfull built-in motor spindle 18000 Rpm HSK63 26/32 kW 124/154 Nm .

Automatic Tool Changer and Chip Conveyor

Automatic tool changer 24 positions, disk type, is standard. Optionally, a 32/40/60 position tool changer and an automatic laser NC4 preset system can be supplied. Chain type chip conveyor is standard.

Integrated ballscrew mounting brackets

The mounting brackets for 3 axis are integrated on the bridge base and saddle casting for the maximum rigidity. This solution allow better rigidity and easier maintenance.

Cooling

Screw nuts are air-oil cooled to draw heat coming from high speed movements. Spindle is water cooled to control thermal effects.

| Axis speed | X | Y | Z |

| BSE 1700 | 30 m/min (1118 ipm) |

||

| BSE 2200 | 24 m/min (945 ipm) | 30 m/min (1118 ipm) | 30 m/min (1118 ipm) |

| Linear axis travel | X | Y | Z |

| BSE 1700 | 1750 mm (68.8’) | 1000 mm (39.3”) | 750 mm (29.5”) |

| BSE 2200 | 2200 mm (86.6”) | 1750 mm (68.8”) | 750 mm (29.5”) |

| Milling spindles | Speed (rpm) | Power/torque (max) | Toolholder |

| 18.000 (opt 24.000) | 32 kW / 154 Nm | HSK63A | |