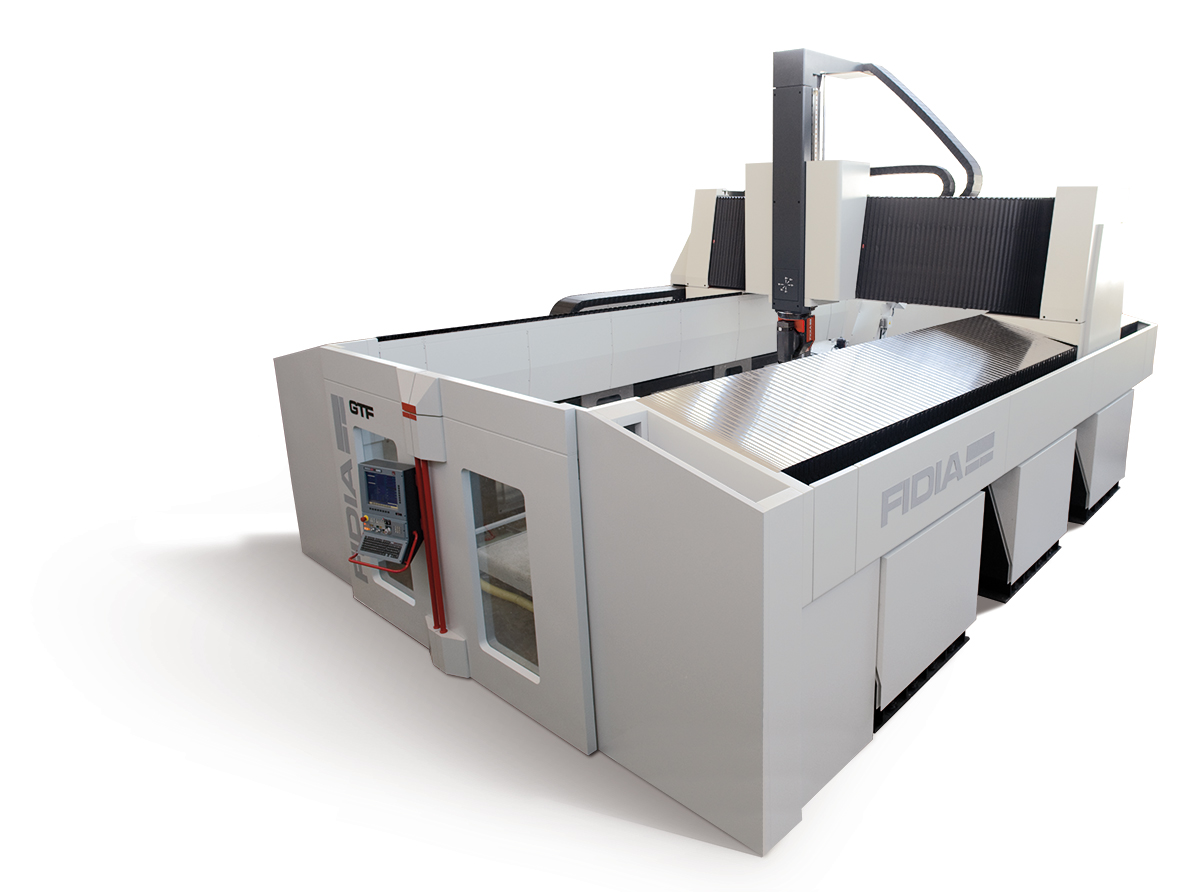

GTF/R

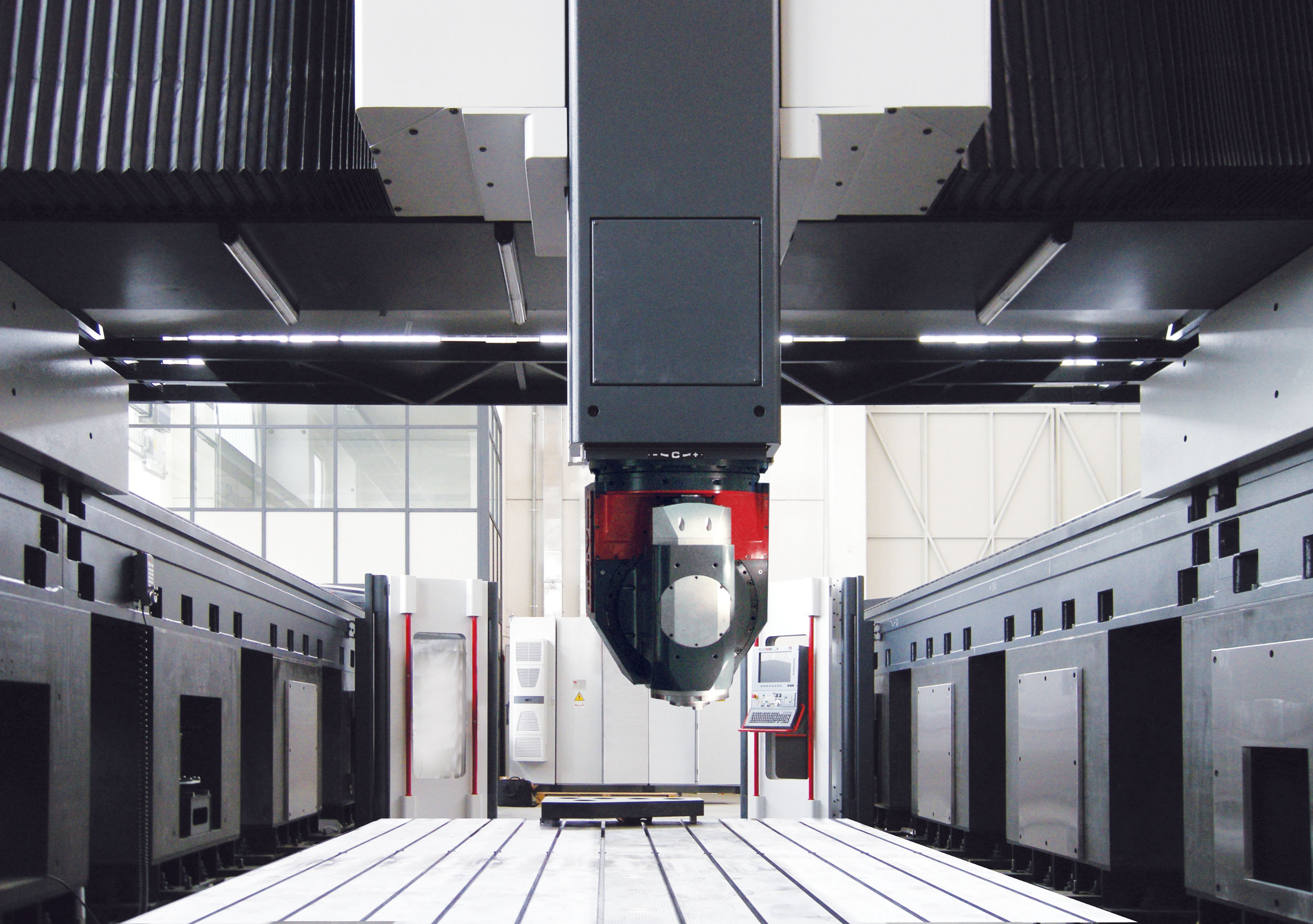

Made of stiff epoxy concrete columns to allow the best vibration dampening effect, these versions of GTF family have the greatest level of modularity, thanks also to the automatic heads changing system. Starting from the smallest 2+2 columns configuration, the same design can be extended to any X axis length just by adding columns.

GTF/R Brochure

GTF Series' brochure

General catalog GTF

Features

| Linear axes travel | X | Y | Z |

| (mm) | 5200 (205”) 7600 (299”) 10000 (394") 12400 (488") 19600 (772") | 2200 (87”) 3500 (138”) 4000 (157”) 5000 (197") | 1000 (39”) to 2500 (99”) |

| Axes speed | |||

| (m/min) | Standard 30 m/min (optional X, Y: 50 m/min - Z: 40 m/min) | ||

| Milling Spindles | Wide selection of Bi-rotary continuous or indexed | ||

| Load capacity | 9000 Kg/m² (1843 lbs/sqft) | ||

| Speed (1/min) | Until 30000 | ||

| Torque (Nm) | Up to 1000 | ||

The GTF/R integrates a 600 x 600 mm ram.

Consequently, this version offers a wide range of heads to choose from:

- M5S with Z strokes from 1000 up to 2500 mm

- M5S2 with Z strokes from 1000 up to 2500 mm

- M5D with Z stokes from 1000 up to 2500 mm

- M5E with Z strokes from 1000 up to 2500 mm

- M5H with strokes up to 2000 mm

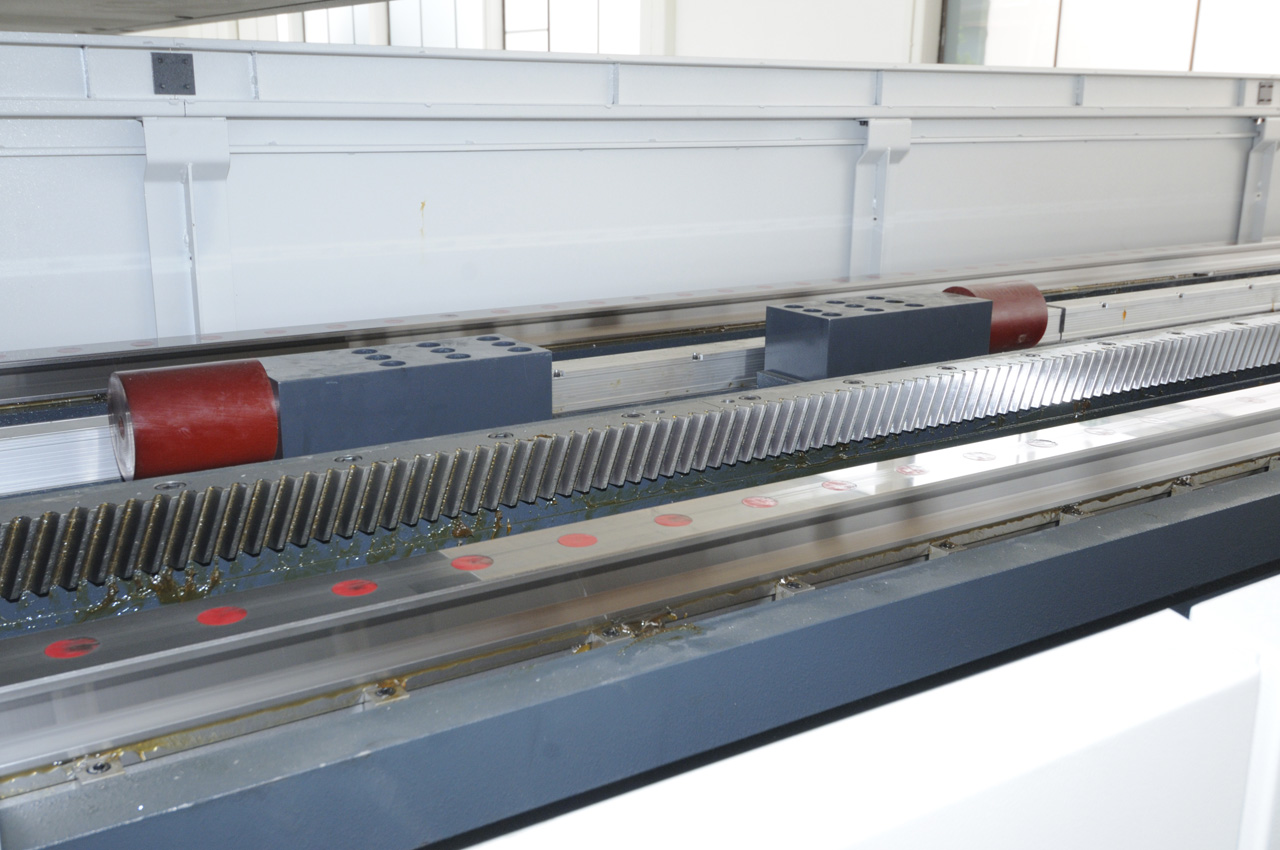

The axes kinematic chains may vary in order to achieve the highest working speed and acceleration. A tandem rack & pinion system drives X and Y axes, while Z axis is driven by rack & pinion, according to the stroke length and application.

Milling heads Fidia on GTF/R

M5A/55 - Continuous bi-rotary head, spindle power 55 KW

M5D - Continuous bi-rotary head, spindle power 100 KW

M5E - Orthogonal bi-rotary head, with interchangeable spindle, 24000-15000 1/min

M5H - High power and torque head, with mechanical transmission and accessory change system, 1100Nm, 34kW

![]()