Milling System 2-K2010/M

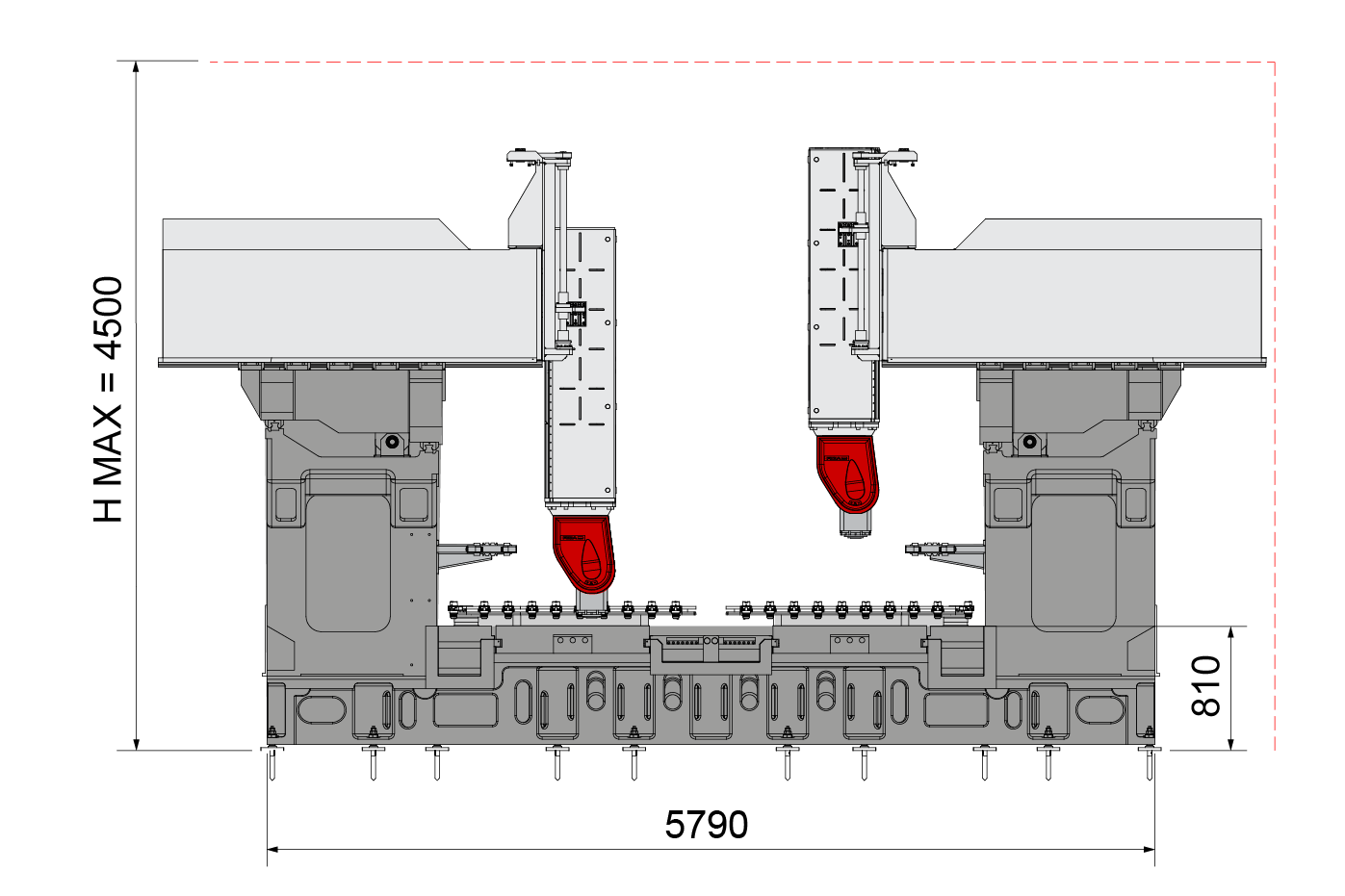

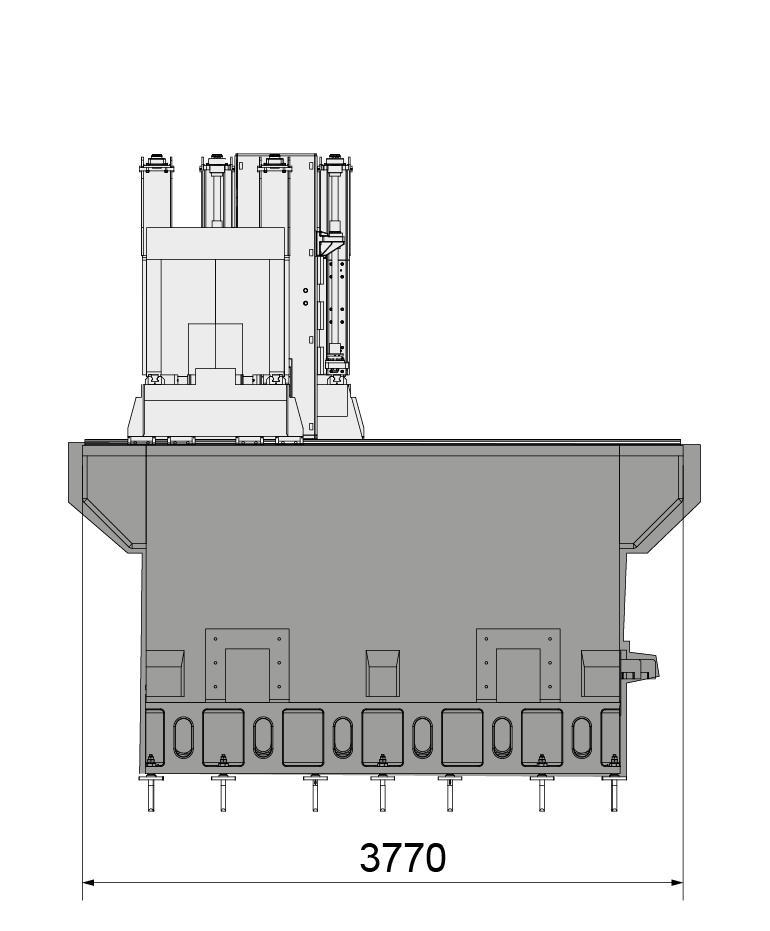

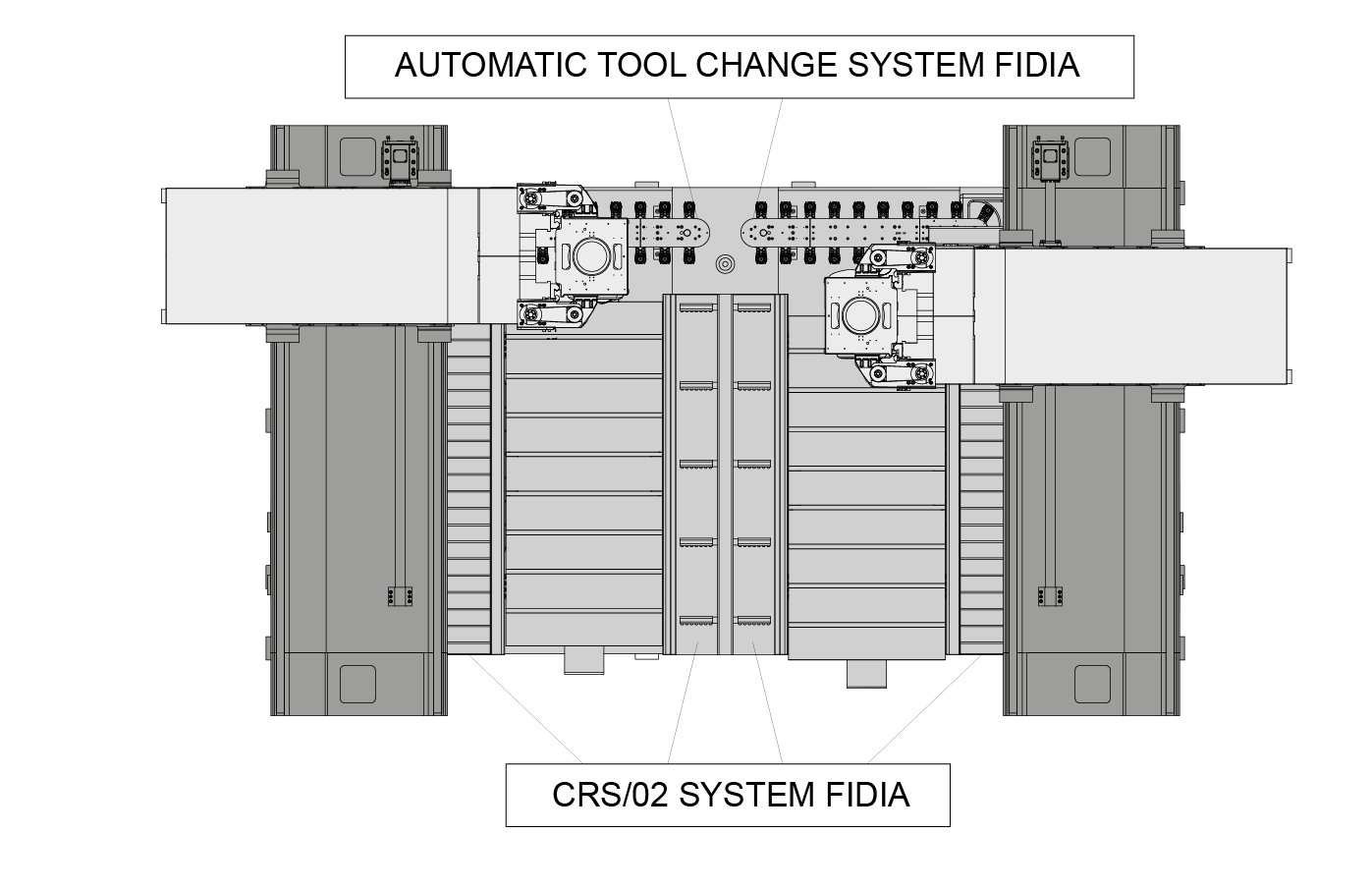

FIDIA’s experience as the sole supplier of an overall solution has made possible this particular configuration: two standard systems, with a shared cast iron table, doubling productivity with respect to other gantry systems having a similar work volume.

This Boxer configuration lends itself to optimum integration with FMS.

Each K2010 module draws on the features and basic structure of the K Range.

K Range' brochure

General catalog KDGH

Features and layout

| Linear axis travel | X | Y | Z |

| (mm) | 2000 (79”)* | 1000 (39”)* | 600-850 (23”-33”) |

| Linear axis speed | |||

| (m/min) | 24 (945 ipm) | ||

| Positioning accuracy | |||

| mm | ± 0,005 (± 0,002") | ||

| Work-piece table | |||

| Dimensions | 2000 x 1000 mm (79" x 39") | ||

| T-Slots | n° 7 - passo 250 mm (10") | ||

| Loading capacity | 7000 kg/m2 | ||

| Tool magazine | |||

| No of positions | 24 - 42 | ||

* +150 mm (6") rotating the C axis with vertical spindle.

Milling head assembled on 2-K2010

M5A/55

The M5A/55 continuous bi-rotary head is ideal for medium-size or large milling machines that perform the complete machining cycle, from roughing out to finishing, where higher torque and power are required in HSC applications.